Polyester Geogrid 60-30

High Tensile Strength & Modulus: The oriented polymer chains in the high-tenacity yarns provide immense load-bearing capacity with relatively low strain, ensuring immediate and effective soil confinement.

Superior Creep Resistance: This is the defining characteristic. Polyester Geogrid exhibits minimal elongation over time under sustained load, a critical factor for the long-term (50-100+ year) design life of permanent structures like retaining walls and embankments.

Excellent Fatigue Resistance: It performs reliably under dynamic and cyclic loading conditions, such as those from heavy traffic or rail lines.

Durability in Common Environments: It demonstrates strong resistance to soil chemicals, microorganisms, and water, ensuring consistent performance. Properly formulated yarns include additives for enhanced UV stability during construction.

Polyester Geogrid: The High-Performance Reinforcement Solution for Demanding Civil Engineering Projects

Introduction: Modern Infrastructure's Engineered Backbone

In the world of geosynthetics, where every project demands a balance of strength, durability, and long-term value, Polyester Geogrid is unmatched as a top-notch reinforcing material. This versatile geosynthetic is made of high-tenacity polyester yarns and specially designed to boast both immense tensile strength and low (unnoticeable) creep—the harmful gradual deformation that occurs under constant loads. Unlike other polymer geogrids, the unique molecular structure of Polyester Geogrid makes it an ideal choice for permanent, critical reinforcement in soil and aggregates. Keeing with this, it provides unparalleled performance in difficult environments where longevity, performance and reliability are a must.

For International B2B buyers, contractors and civil engineers involved in large-scale infrastructure, transportation and environmental projects, understanding the technical superiority and specific applications of Polyester Geogrid is essential to specifying materials that ensure both structural integrity and low lifecycle cost as well as eventually even saving money. It details how Polyester Geogrid may be incorporated into many aspects of civil engineering projects: providing a foundation for the roadbed, treatment of fill soil beneath foundations and other large scale structures.

Product Characteristics: Engineered for Endurance and the Long Term

A core position of Polyester Geogrid is 1, 2 and 5:3 high soil modulus properties, keeping the Reinforced Soil as firm trenches of 'free earth' that slip and do not crumble under external loads.(Sophisticated Chinese characters produce cracks of 300 micron width in reinforced soil from slurry whereas all this damage will happen elsewhere before touching high modulus Polyester Geogrid) In turn, these three properties define whether Reinforced soil can function at all--which is called its structure and stability.

Core Material Science: Polyester is Best in Show!

The polyester material PET (polyethylene terephthalate) is fundamental to our product performance while the high-tenacity polyester yarns do the work up top.

One material change, two properties take a dramatic turn: polyester geogrid now has both high tensile strength (more than twice the original value) and modulus at low strain. These oriented polymer chains undergo minimal permanent deformation on reaching their yield point which allows them to immediately reinforce soils without any intermediate (or at all) slippage Super Creep Resistance: This is Polyester Geogrid's outstanding feature. it exhibits minimal elongation over time under sustained load, an important characteristic for the long-term (50~100 years and more) design life of permanent structures such as retaining walls and embankments.

Excellent fatigue resistance: It performs reliably under dynamic and cyclic loading conditions such as those from heavy traffic or rail lines.

High performance in the face of normal environmental conditions: The strength of polyester Geogrid does not change with time or load; it withstands soil chemicals, micro-organisms, and water well. Special additives to enhance UV stability have been put into the making of properly composed yarns.

Method of Manufacture and Structure:

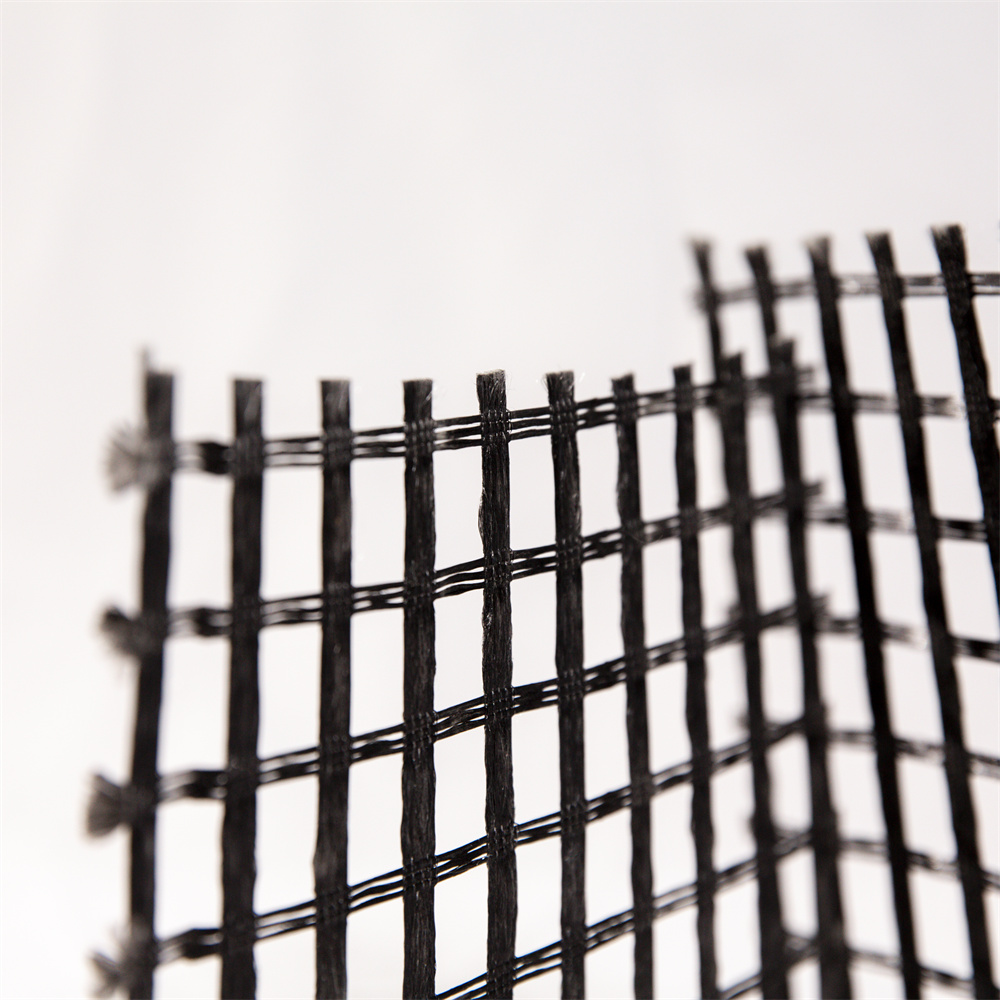

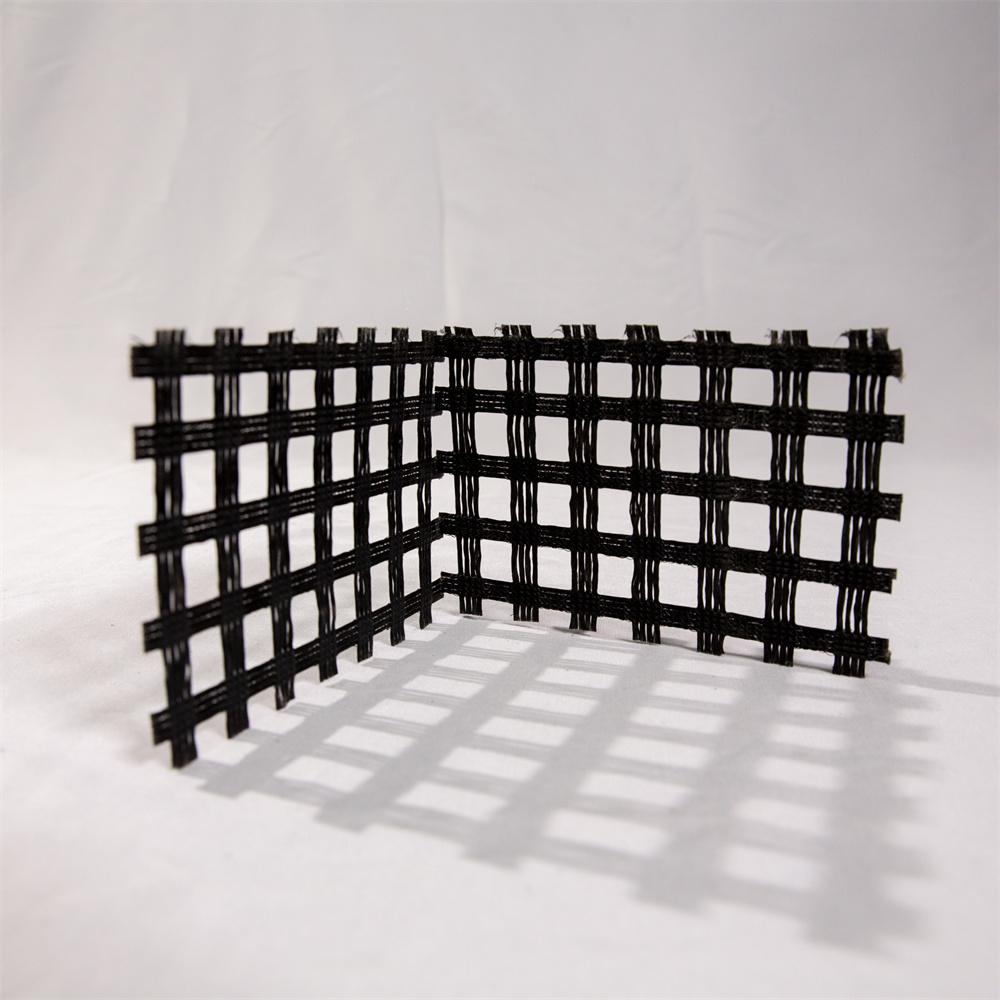

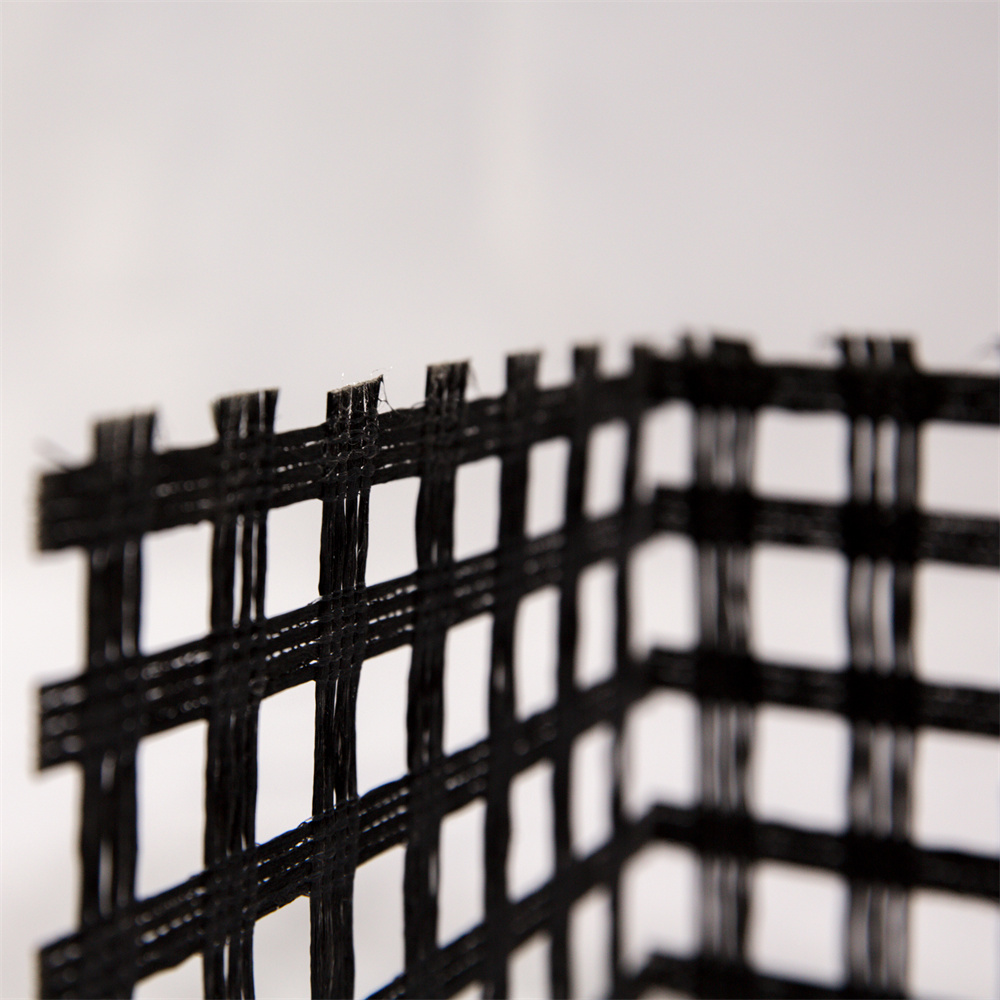

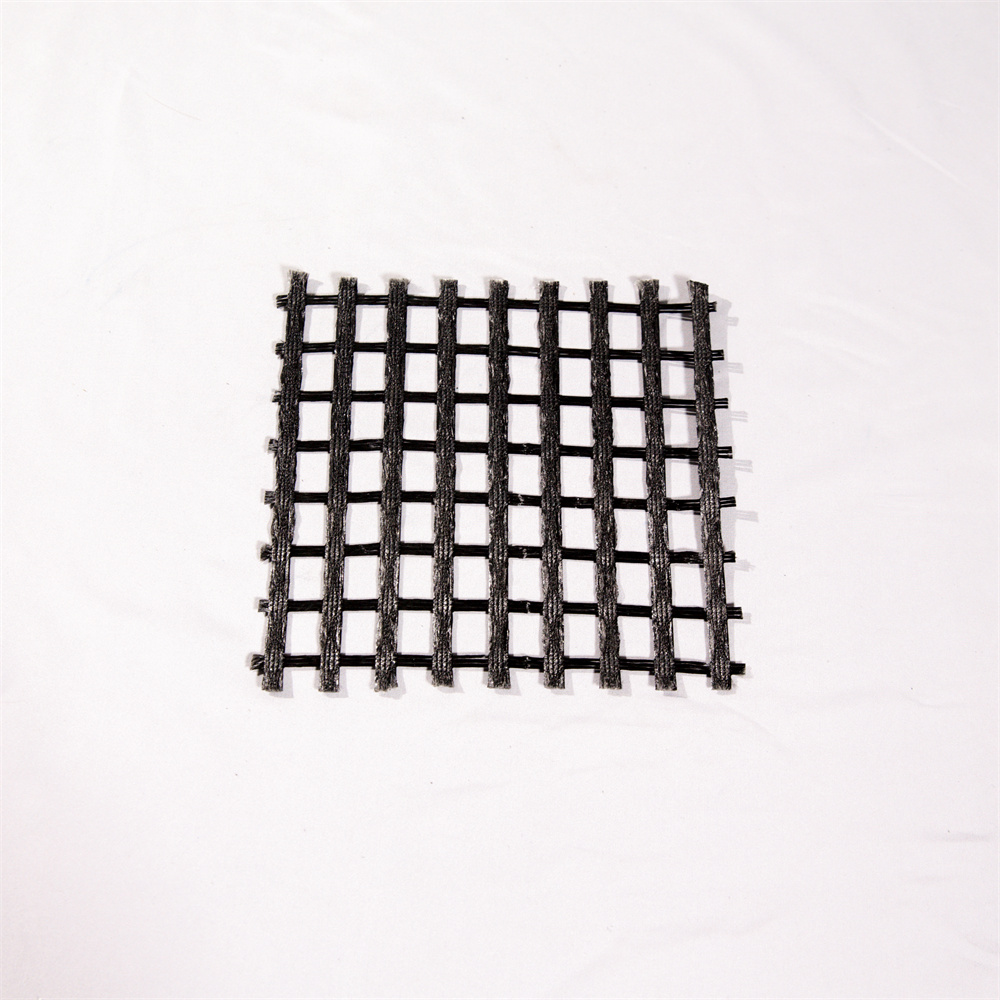

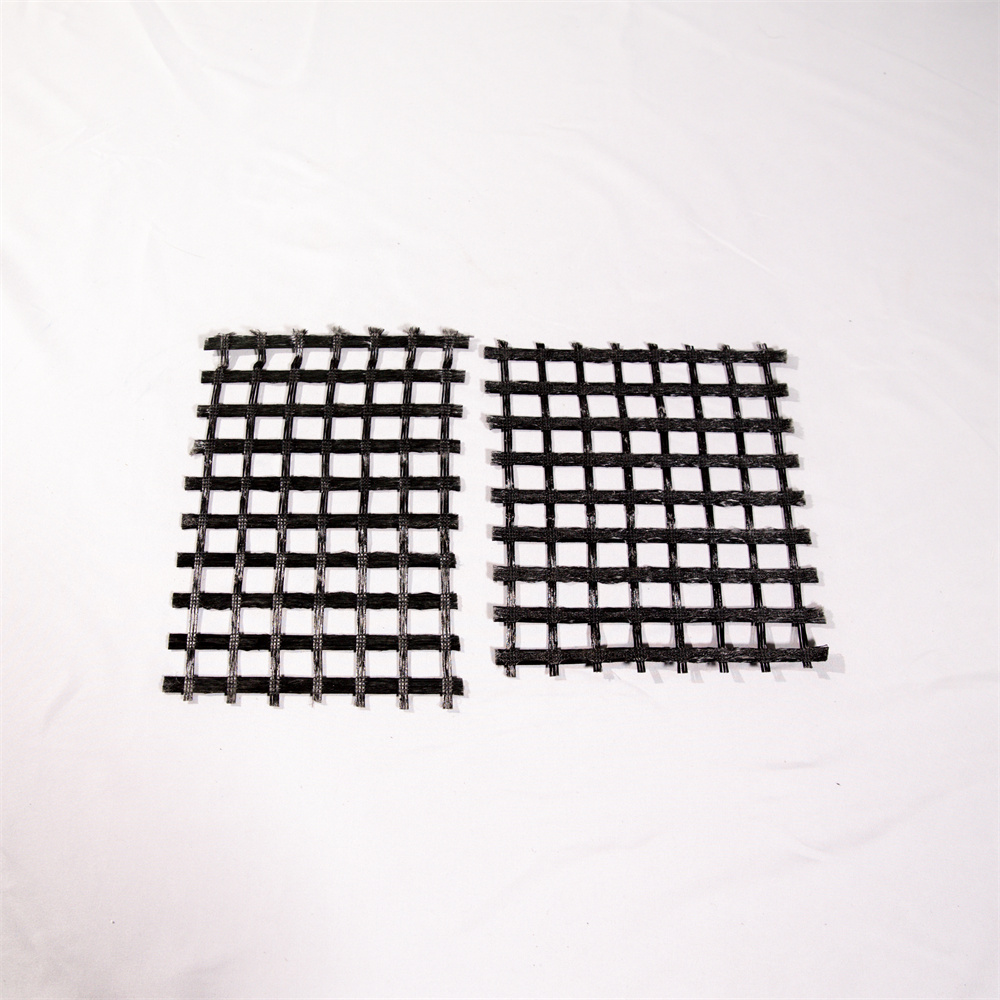

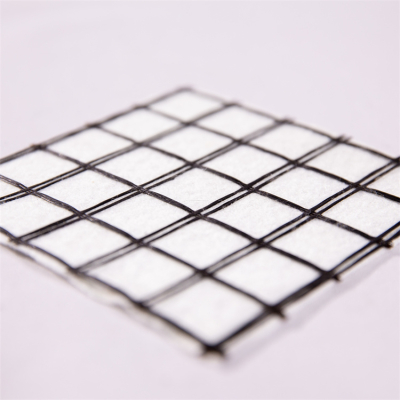

Polyester Geogrid is usually made by strong weaving or knitting techniques.

Spinning and Twisting into Yarn: High-strength polyester filaments are drawn out to be yarn.

Coating: With a protective polymer such as PVC or our own proprietary blend, yarns are usually made so as to bear up under wear well also giving strength at the joint between them.

Formation of Grid: These coated yarns are woven or knitted into an integrated grid structure with integral nodes, where it is crucial for quality control to have overlapping points along the length and transverse direction. Such nodes are necessary in order to bear the load transferred by each rib with respect to both its length and width as well as being an important inspection point.

Weave Patterns: These resulting apertures are constructed so as to achieve an optimal level of mechanical interlock with a wide variety of fill materials, from granular soils to recycled aggregates and crushed rock.

Key Advantages and Functions:

Application of Polyester Geogrid directly translates into real, measurable benefits for the developers, engineers, and builders of at construction site.

Aged Performance without Equal

With its excellent resistance to creeping, the factory-made bias of the polyester softwares continues to guarantee design maximums throughout all conditions of use over many years. As a result, strengthened polyester geogrid can generally be considered good investment at modest risk for a permanent project.

High Structural Efficiency

The combination of high tensile strength and excellent aperture stability means narrower, more space-efficient earth slopes can be built. Retaining walls may also be made higher still. This will have substantial benefits for the cost of land and the amount of fill needed.

Adaptation to Various Fill Materials

Whether you're using top-quality fill materials or second-rate stuff, it all becomes much more manageable thanks to Polyester Geogrid shear strength. It interfaces well with cohesion soils and on the other hand gives freedom of design to engineers.

Cost-effectiveness over entire lifecycle

While the upfront cost can be higher than some alternatives, lesser maintenance requirements as time goes on, increased durability, and design optimization, all contribute to make it the most cost-effective choice for critical applications. It is a classic case of cost-effective soil reinforcement.

Simple Construction, Rapid Deplroyation

Being supplied in rolls comfortable to handle, Polyester Geogrid is installed with great speed. Its strength means that it holds up well during placement and filling of embankment materials, so that the construction timetable isnt ruffled.

Principal Application Areas

In a number of sectors, Polyester Geogrid has become the specification of choice for tough, long lasting reinforcement.

Mechanically Stabilized Earth (MSE) Walls

This is a flagship application. Layers of Polyester Geogrid are inserted between compacted soil layers to form a cohesive, gravity-resistant mass immediately behind the wall facing (usually concrete panels, blocks). It provides the means to build safe, robust, aesthetically adaptable walling for roads, bridges, and commercial sites.

Reinforced Steep Slopes and Embankments

Reinforcement with Polyester Geogrid allows for the construction of robust, planted slopes with much steeper than natural slope angles. This method saves right-of-way requirements and cuts the environmental impact considerably.

Foundation and Embankment Reinforcement

On very soft or weak subsoils, one or more layers of Polyester Geogrid can be used to give a stable working platform or to increase the weight loading capacity for embankments and structures. That means less settling and in many instances can avoid the need for deep foundations.

Sanitary Landfills and Containment Facility Engineering

In sanitary landfills, it is used in liner systems and final cover systems to reinforce the overlying soil above the geomembrane and help to stabilize slopes on containment levees, ensuring long term integrity.

Overview of installation:

Proper installation is critical for performance. Key points to bear in mind include:

Preparation of a flat and hard work surface.

Unrolling the roll of Polyester Geogrid in the direction of the design (usually at right angles to the slope).

In accordance with the prescribed overlap, which is not less than 150 mm, fix the geogrid with connecting bars or tubular clips when necessary.

Place the fill through thin lifts on the geogrid and compact it carefully, working from the anchored end out to motion can be minimized.

FAQ of Water-soluble Geogrid

Q1: What's the biggest difference between polyester geogrid and polypropylene (PP) geogrid, and how do I decide between them?

A: The primary difference is in creep resistance and chemical tolerances. Polyester geogrid does well in long term creep testes, making it a default choice for permanent, critical structures like deep retaining walls. PP geogrid is suitable for application sites such as basal reinforcement where it is acceptable to accept some long term strain, but not so good at resisting oxidation in high pH environments (e.g., lime-stabilized slopes). Choice depends upon design life, soil pH, and Structural criticality.

Q2: What effect does a Polyester Geogrid with strong junctions have on performance?

A: Junction strength is crucial: It decides how effectively tensile forces are distributed from the longitudinal ribs -- carrying the main load -- out to the transverse ribs and throughout the entire latticework structure.

Q3: Can Polyester Geogrid be used in high-pH (alkaline) environments, like behind concrete retaining walls or in soil that has been treated with lime?

A: This is defined very carefully. Regular polyester can disintegrate in environments that are consistently too alkaline (>pH 10). For such applications you must specify a modified or high-tenacity coated polyester geogrid, which has been developed to resist alkaline hydrolysis with specialized coatings and polymer blends. Provide your soil chemistry data to your supplier for a tailored recommendation.

Q4: Certification and test reports are necessary if you want to ship Polyester Geogrid for an international project abroad. A: Demand comprehensive documentation. This includes: - Third- Party Test Reports: for tensile strength (ASTM D6637) None - Junction Strength None - Creep Resistance (Such as GRI GG4) None - Durability (Such as hydrolysis resistance) - Certificates of Conformance (COC): Certifying that the product submitted for shipment meets the project's technical specifications. - Regional Approvals: This may require CE Marking (Europe) with its declared performance, or other country-specific homologations (e.g. AASHTO in the USA And Good Polyester Geogrid manufacturers will provide this as standard.anchored text

Workshop

Customer Visit