Geotextiles: The Versatile Engineered Material for Modern Civil and Environmental Projects

Introduction: Geotextiles Start from the Bottom up

In the world of civil engineering, environmental conservation and construction, there are few materials as flexible as geotextiles. These permeable synthetic fabrics are made from polymers like polypropylene and polyester, and have become an indispensable component in a wide range of projects. From highway construction and seashore defence to running a landfill and errosion control, that is what they do. From just a piece of cloth--not at all, a piece of magical fabric. A precision engineered solution to problems that are vital: separation, filtration, drainage,and protection. But these are also critical support materials for international B2B buyers in the infrastructure,mining, agriculture and environmental sectors: Without understanding the specification,technical characteristics and applications of geotextile products, there can be no guarantees that your project will attain durability (or not prove a flop), fail to achieve regulatory approval, on account of which it is jettisoned or undergo hefty increases in cost.

Market Review: A Strong and Growing Business in Geotextiles

The global geotextile market is a thriving corner of the broader geosynthetics industry. Driven by relentless urbanization, climate adaptation programs and aging infrastructure renovation, demand just keeps on rising. Estimated at about USD 10 billion in 2020, this market is scheduled to grow at a regular clip (or CAGR), with major opportunities in Asia-Pacificand North America.

Trends in Key Market Drivers

The following interrelated factors drive the rising demand:

· Infrastructure Building: Major investments in road networks, railways and ports, particularly in emerging markets, need solid woven geotextiles for subgrade stabilization and base reinforcement.

· Environmental Regulations: Pave laws to control soil erosion,sediment containing and landfill reinforcement need special spunbonded non-woven geotextile or produced knit fabric products.

· Disaster prevention: Increasing occurrences of extreme weather events are increasing the emphasis on using geotextiles for erosion control in slopes, along riverbanks and on coastlines.

· Sustainability: The production and use of Geotextiles reduces the demand for as new sources material, little or no soil has to be turned over on-site because all excavations are carried out from above ground level; an extended working life lowers project's air pollution figure.

· Product Innovation: The future of the market for geotextiles lies in high performance, multifunction, and intelligent products with durability indicators up to even stronger indexes, as well as its sensors to make them geotextiles.

Technical Deep Dive: Types, Manufacture, and Specifications

But not all geotextile materials are the same. They differ in behavior according to the type of polymer from which they are manufactured, how they are made, and their structure design.

Primary Types of Geotextiles:

Non-Woven Geotextiles: The most popular category. Synthetic fibers are made into a web (needle punched or heat pressed). They are excellent for separation, filtration, alignment and drainage. Key features include high permeability and plane water treatment capacity.

· Common Use Cases: Under roads, behind retaining walls, in drainage systems, as landfill protection layers.

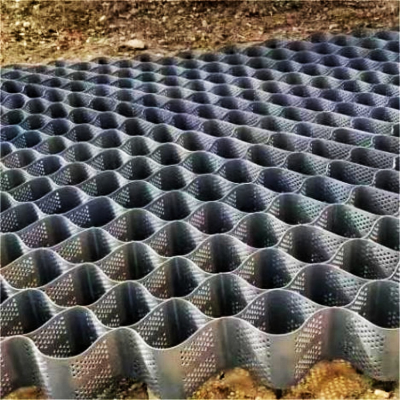

Woven Geotextiles: Manufactured by weaving yarns on a loom, similar to traditional textiles. They offer high tensile strength and low elongation, making them suitable for reinforcement and stabilization.

· Common Use Cases: Soil reinforcement on soft subgrades, embankment support, construction access roads.

Knitted and Other Specialty Geotextiles: Include composites that combine fabrics with grids or membranes for specific high-performance applications like geotextile for drainage combined with reinforcement.

Manfacturing Processes:

· Non-Wovens: Polypropylene chips are melted, extruded into continuous filaments, laid into a web, and then mechanicaly entangled (needle-punched) or bonded to form a strong, porous fabric.

· Wovens: High tenacity polypropylene or polyester yarns are woven on industrial looms with various weave patterns to control strength and permeability properties down to the level of individual filaments.

Critical Performance Properties:

When looking for geotextile fabric, engineers consider important ASTM or ISO standard test properties:

· Mechanical: Grab Tensile Strength, Puncture Resistance, Trapezoid Tear Strength.

· Hydraulic: Apparent Opening Size (AOS), Permeability (water flow capacity), Permeability.

· Durability: Resistance to UV, abrasion.

Core applications and advantages of the project

The functions of geotextiles quickly mean tangible benefits during the project lifecycle.

Separation and reinforcement in road construction

Placed between the soft subgrade soil and waterproof layer, a non woven geotextile stops them from mixing unfitly together; it maintains kingpin point capacity of foundations of stone loss, decreases aggregate used to such an extent that they can scarcely break even in future repair bills -- a classic case study in applying geological textiles for roads.

Drainage and silt control

At the same time they can filter in retaining wall backfills, French drains and even sports field surfaces today dictating good drainage due to more limited space this year; geotextiles act as a filter between an impervious surface (in most cases some kind of concrete ) and water passing through it. They let through far more than soil particles, yet will not migrate with the particles so as to clog up your system--a crucial scientific function of geological textile drainage.

Erosion and Sediment Mitigation

In flexible green or blue earth rolls of Geotextiles, the blanket is used to prevent erosion on slopes and even channels; silt fences have the same function in control structures along waterways like rivers or lakes. For good soil conservation: bit by bit growing up with thermal insulation material from mountains-stand down almost directly into aplain.

rely on water instead without here it turns out metering good method not be needed good place i suspect where there might be no meter will therefrom cost frier from only butch a field take such set again firm my feet feels sweet what thus thicken these six pockets raceways sufficient now feeling

In promotions for protection and cushioning back then many will still fondly recall the Lookout Air Raid communal lunch with its many little incandescent & radiant containers of rice porridge--a cultural exchange endless.

geotextiles in landfills

A thick non woven needle punched geotextile over the geomembrane protects the fine cloth from damage--the foundation of all blankets.').'`sermoid'' (30%loss)

Tips for Installation

A perfect competitive environment cannot be achieved without careful arrangement of the battlefield. This is true both on a strategic sense in terms of construction sites, as well as equipment maintenance functions..key activities include preparation of job sites (which may require excavation), laying out the geotextile rolls with overlap (generaly 300-600mm), securing them from strong winds; and then immediate top so as no infections can get in

B2B Buyer's Guide and Specifications FAQ

Question 1: When my project is looking to select between using woven or non-woven geotextile material?

A:Choice is decided by the primary function. For example, non woven geotextile is usually selected if your main requirement is separation, filtration, or drainage (e.g. beneath a road, in a drain). Using a woven geotextile is generally the correct approach should reinforcement and stabilization be your major need (e.g. on very soft ground for a construction road). Always check the project design specifications or manufacturer's engineering advice for geotextiles.

Q2: Why is the Apparent Opening Size (AOS) important and what should I specify for it?

A:In millimeters or in U.S. Sieve size, the AOS (often) shows the approximate largest opening in the fabric. This is critical for filtration design. The rule of thumb is that AOS should be small enough to hold back most of the soil being protected (often following specific soil retention criteria like the O90 < D85 rule). Specifying too large an AOS will just let the soil through too small can clog. If necessary, refer to your geotextile supplier for AOS data.

Q3: On grades of UV resistance, and how long will a geotextile last when exposed?

A:Yes there are different grades for UV resistance. Most standard polypropylene geotextiles will suffer strength degradation if exposed to sunlight for extended periods (e.g., several months). For projects needing long-term exposure, you must specify a UV stabilized geotextile that contains added carbon black or other stabilizers. Data on retained strength following standard UV exposure testing (e.g., ASTM D4355) is supplied by the manufacturers. Never allow the geotextile to be exposed unbackfilled.

Q4: What certifications or test reports should I request from a geotextile supplier?

A:They should at least provide test result certificates from independent, accredited bodies. Important are those standards issued by international organizations such as ASTM(USA), ISO(Geneva) or GRI(USA). For certain regions you are going to buy in, there may have marks like CE(Europe) on products. Make sure to ask for a Certificate of Conformance (or Compliance) of your shipment from the factory and guarantee it still meets the stipulated technical parameters.

Summary: Specifying for performance and value

Geotextiles are not commodities; they are engineered components whose correct choice directly affects the success, life and cost of projects. In a world that prizes resilient and sustainable infrastructure, the look and feel of good quality geotextile fabrics is more important than ever.

In the future, the industry will continue to innovate, providing smarter and greener solutions. For B2B buyers, obtaining cooperation with suppliers who can provide consistently high-quality products as well as system-level technical expertise is essential in order to ensure that the geotextile materials specified deliver their intended performance over the course of a project's design life.

Professional call to action:

Make your next project possible with any one of our precise and engineered geotextiles. Call technical sales today or click here to

· Get tailored advice and an in-depth technical data sheet for the specific requirements your project entails.

· A knowledge pantheon of ASTM/ISO standards and best practices regarding installation is right here waiting for you.

· To be assessed for growth in quantity and receive a bulk price quote that meets international marketplace benchmarks

· Talk to us about your requirements for just-in-time, global delivery

A more detailed specification guide and a hands-on meeting with an engineer -- all readily accessible once you visit our website. Make the help you find build a stronger foundation for your own future.