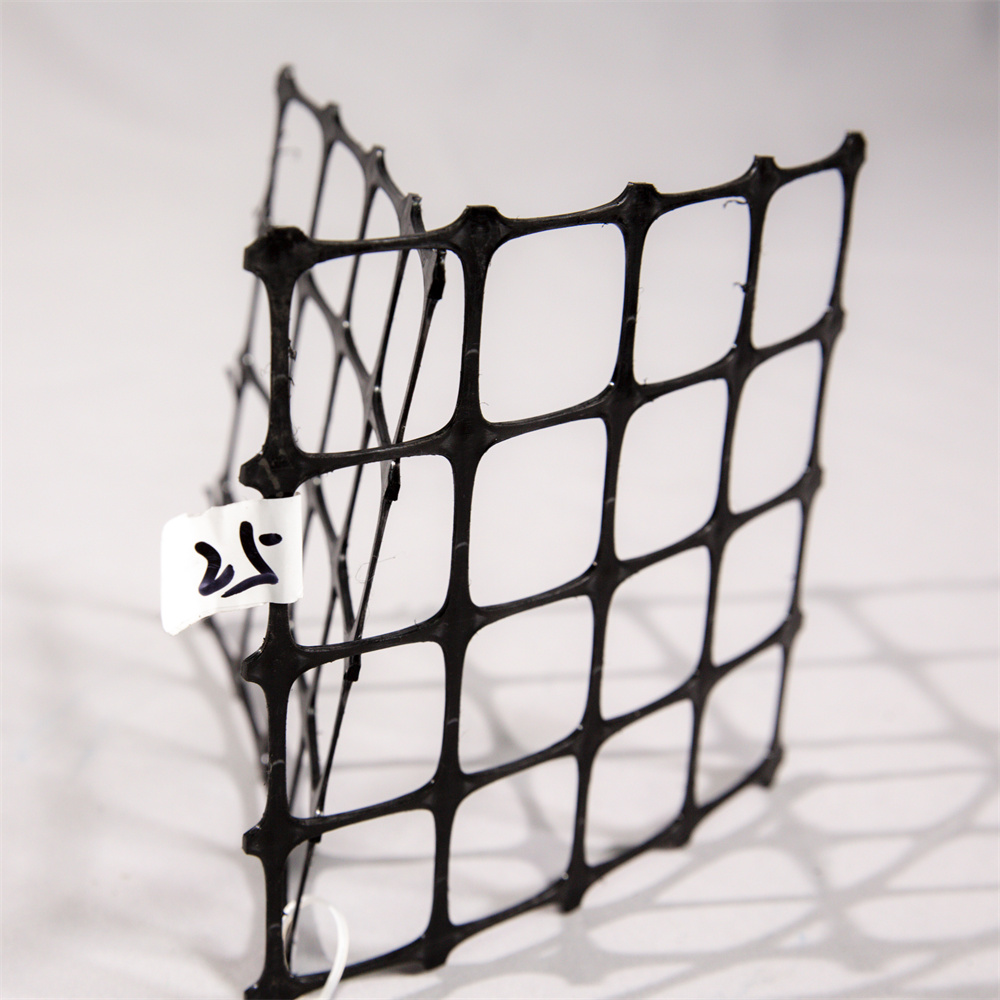

The PP Biaxial Geogrid is the solution you need for all soil reinforcement or ground stabilization.

The Biaxial Geogrid is the solution you need for all soil reinforcement or ground stabilization.

An Introduction to Modern Construction.* The Vital Role of Corporate Geosynthetics In the current heart is the demand for stable, low-cost solutions to ground stabilization, even as road construction and infrastructure development accelerates globally. In the field of geosynthetic materials available, PP biaxial geogrid has become an indispensable part of the kit for engineers and contractors facing difficult soil conditions. This engineered polymer grid, made from high quality polypropylene, provides just as much strength in its longitudinal and transverse directions hence making it not only for bad land reinforcement work but also necessary from a standpoint of load distribution. It has become possible to save money with variations on this simple theme: with on-site pipework as the only alternative product and levy to environmental disruption there is no doubt that one is more likely than the other.

The versatility of polypropylene biaxial geogrid also stretches across many fields and industries: from transportation and civil engineering to mining and environmental projects. As sustainability becomes increasingly important within construction, these geogrids offer an environmentally friendly alternative to traditional methods (by reducing one's need for aggregates and interfering with the environment on a smaller scale).

The Expanding Geogrid Industry Market Analysis: Current Market Trends and Forecasts The global geosynthetics market was valued at about $12.5 billion in 2023, and is expected to grow from 6% to 8% annually through 2030. Note that Longzhu welded geogrid products occupy a larger proportion of this market because they have no more popularity in regions seeing rapid infrastructure development. Consumption soothes: Asia-Pacific area leads, then North America and Europe, with poor nations coming up fastest.

Key Economic Forces Forces pushing up demand for PP geogrid in the field of soil stabilization Environmental Regulations Environmentally sound infrastructure brings its own rewards. This is why government initiatives all over the world are pouring vast sums of money into new roads, railways and harbours

Urbanization Pressures. Population growth has created a need for more stable foundations in cities to take all the new buildings and transport

Environmental Regulations Elaborate new rulings on environmental protection will benefit any solution that causes minimal disturbance of the land and employs minimal amounts of material.

What Advancements Has Technology Contributed?

Through improved manufacturing processes higherperformance materials are produced, which have great consistency

The market is going toward high-specification products that possess greater durability and predictable long-term reliability. Heavy duty biaxial geogrid is increasingly specified for demanding applications.

Technical specifications and manufacturing capacity

Why polypropylene?--The science of plastics

Polypropylene biaxial geogrid offers distinct advantages that are suitable for geotechnical applications:

· Chemical resistance: Corrosion resistance to acids, alkalis and soil chemicals

· Biological inertia: Will not undergo biological degradation by microorganisms

· Low moisture absorption: Retains mechanical properties for wet environments

· Durability: Properly formulated PP retains performance for decades

Advanced Manufacturing Processes

The manufacture of high-strength biaxial geogrid goes through some sophisticated engineering processes:

Extrusion: Polypropylene particles are melted and extruded into flat sheets with controlled thickness

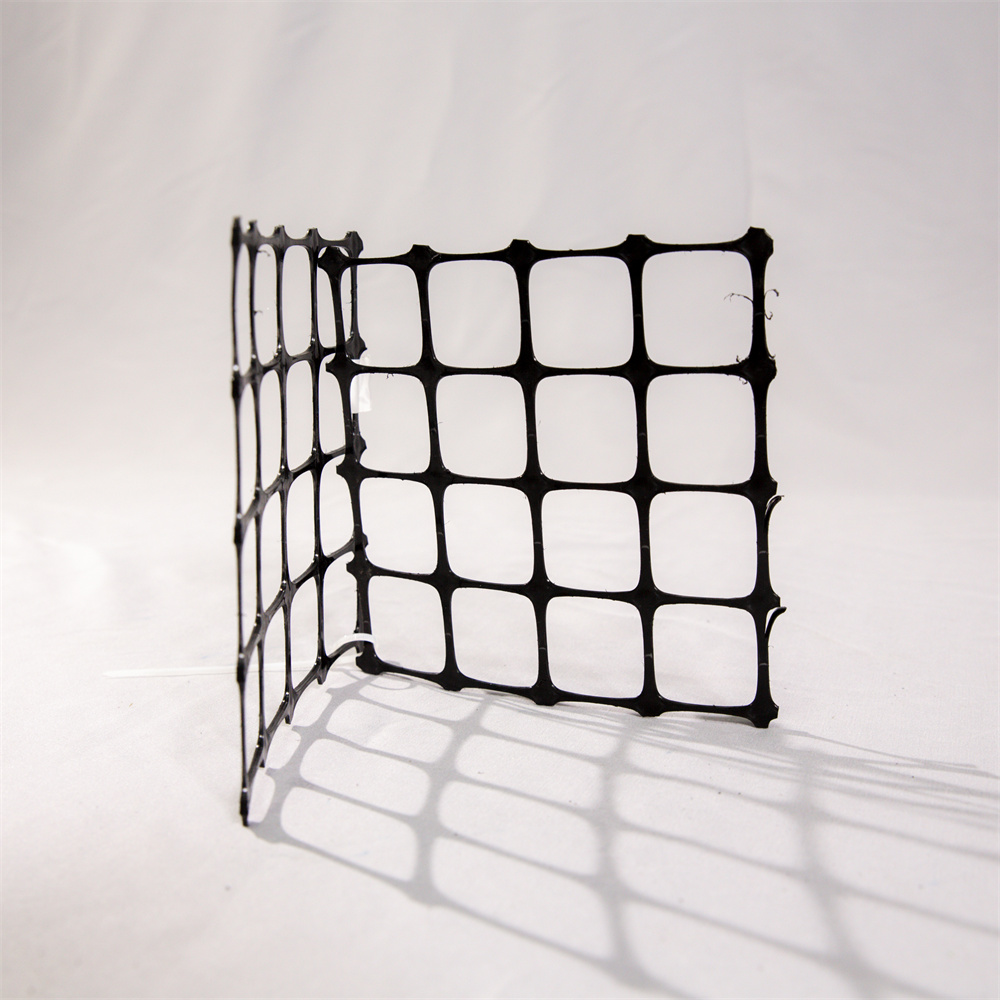

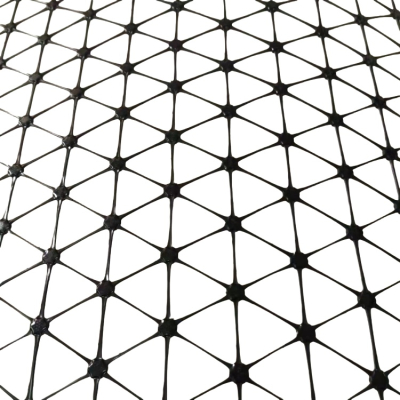

Punching: Using precision punching equipment, regular pattern apertures are formed

Biaxial Stretching: The punched sheet is stretched in both machine and cross-machine direction under controlled conditions

Annealing: Heat treatment stabilizes the molecular orientation created during stretching

Quality Control: Every batch is subjected to rigorous testing for tensile strength, aperture dimensions and junction efficiency

This manufacturing process produces collectively formed junctions where ribs intersect, ensuring optimal load transfer characteristics through the entire grid structure. The resulting geotextile biaxial geogrid shows predictable mechanical properties but also exhibits excellent creep resistance.

Engineered Applications and Performance Gains

Principal Applications of PP Biaxial Geogrid

In road construction biaxial geogrid serves several critical functions:

Reinforcement and Stabilization as Road Base

When placed in unbound aggregate layers,PP biaxial geogrid will form a mechanically stabilized layer that:

· Reduces aggregate thickness requirements by approximately 40%

· Disperses the weight of the load over weak subgrades

· Prolongs pavement life by reducing reflective cracking

· Minimizes rutting in flexible pavements

Support Systems for Foundations

Where structures are built on marginal soils,geogrid used for foundation stabilization gives:

· Enhanced bearing capacity

· Reduced differential settlement: This can be due to better understanding of lateral soil pressures near foundations

· Improved seismic performance through soil confinement: Directly contributes to greater seismic stability in structures such as earth dikes, bridges, and earth dams. Also helps reduce lateral earth pressures on retaining walls

· Alternatives to deep foundations that are cost-effective: a topic of great interest in the current market

Specialized Applications

· Mining and heavy industrial areas: For haul road construction and equipment maintenance accessways

· Port and terminal facilities: Stabilization of the container yard, and crane loading points

· Railway ballast reinforcement: Reducing frequency of maintenance on rail networks-Landfill construction: Base reinforcement, slope reinforcement.Positioning Best Practices

Proper placement techniques are essential for ensuring that PP biaxial geogrid delivers its full performance:

Site Preparation: Ensure good sub-grade consolidation and leveling

Material Placement: Unroll geogrid with major strength direction perpendicular to traffic direction it will be used in

Overlapping and Connection: Maintain specified overlaps as required (usually 15-30 cm) and join with appropriate connectors

Backfilling Techniques: Initial fill should be laid down carefully to avoid misplacement, then compacted in steps or layers based on the thickness of each thin lift

Quality Assurance: Photograph installation and control position of material before coveringComparative Advantages and Technological Innovations

How PP biaxial geogrid compares with alternative materials

PP biaxial geogrid offers several advantages over uniaxial geogrids and conventional reinforcement techniques. These include direction-strength: enhanced reinforcement throughout the structure

· Bidirectional Strength: Equal or nearly equal strengths in both directions, providing complete stabilization

· Aperture geometry: Advanced shapes embedded in an optimized array strengthen geogrid-to-aggregate interlock.

· Junction Integrity: Complete singularly formed joints resist damage under multidirectional loading.

· Long-term performance: Good creep resistance ensures the design life of 75 years in most circumstancesRecent Technological Advancements

To improve biaxial geogrid performance, leading manufacturers are stepping up their innovation. This includes

· Surface Texturing: Improving surface characteristics to increase soil-geogrid interaction

· Hybrid Composites: Combination with non-woven geotextiles to combine separation and filtration functions

· Smart Manufacturing: Advanced process controls for consistent product performance

· Environmental Adaptations: Special formulae for wide temperature ranges and adverse chemical environments

FAQ: Buyer’s Questions and Professional answers

Q1: What is the typical design life for PP biaxial geogrid in pavements?

A: Polypropylene biaxial geogrid that has been correctly specified and installed can typically be expected to outlast 75 years in pavement applications. As is always the case, the actual working life will depend upon environmental conditions, loading patterns, and the standard of installation. Most manufacturers provide reduction factors for creep and environmental degradation in the technical data sheets from which precisely engineered calculations can be recovered.

Q2: In what applications is biaxial geogrid superior to uniaxial?

A:Biaxial Geogrid in soil stabilization provides strength in two directions and is mainly devoted to relieving pressure over weak subgrades, such as can be found in road bases and working platforms. Uniaxial Geogrids are really strong in one direction only and are commonly used for reinforcement on slopes and retaining walls where the forces are primarily unidirectional. The choice will depend on the specific problem in your application.

Q3: Which PP biaxial geogrid certifications should I look for when I’m buying it?

A:Well-known manufacturers should be able to supply products that conform to ISO 10319, ASTM D6637, etc. The CE mark (for Europe), plus national approvals (AASHTO in the US) are further indications of compliance with regional requirements. Routine testing reports should always be submitted for critical performance parameters.

Q4: Can biaxial PP geogrid be used for permanent applications that are exposed?

A:While PP Biaxial Geogrid has excellent durability, polypropylene will suffer prolonged UV exposure. For permanently exposed applications, put UV-stabilised formulations with a suitable carbon black content. For temporary exposure’ under construction conditions (typically up to six months), standard formulations are generally quite sufficient. Check with the manufacturers’ instructions for specific exposure recommendations.

Conclusion: Engineering a More Stable Future

The development of PP biaxial geogrid technology represents a major breakthrough in geotechnical engineering, solving the problems of ground stabilization with reliable and affordable means. Now, when the demands of infrastructure are increasingly diverse, these engineered materials provide modern construction projects with the predictability of performance called for by the times.

When choosing biaxial geogrid for civil engineering projects, look for a supplier with extensive technical support, reliable certification data, and successful project experience. Preferably, a manufacturer should not only produce top-quality items but also provide application engineering assistance to guarantee the best results from a project.