Fiberglass Geogrid: The High-Strength Reinforcement Solution for Demanding Infrastructure

Introduction: The Critical Role of Advanced Geosynthetics

There are many standard solutions that fail in modern civil engineering. Infrastructure is being pushed to its breaking point by more heavy loads, tougher environments, and the requirement for extremelongevity. Fiberglass geogrid is different and impressively better: this geosynthetic material performs well under these special conditions. Unlike traditional polymer geogrids, fiberglass geogrid is manufactured from continuous glass filaments that are coated with a protectivit polymeric layer. The result is a product notable for its extremely high tensile strength, little fatigue and superior resistance to environmental degradation.

In those special-purpose projects where performance must reign supreme, fiberglass geogrid has already begun to carve out a crucial niche; everywhere from preventing reflective cracking in asphalt overlays to supporting base layers underneath heavy industrial slabs, the unique nature of its mesh makes it essential for engineers and contractors alike worldwide. For international B2B purchasers engaged in roads, highways, airports or logistic s hubs who rely on the durability of their goods–and warranties-that they specify, realizing these potential applications becomes an essential part of the knowledgebase.

Market Dynamics and Growth Drivers for Fiberglass Geogrid

The worldwide market for advanced geosynthetics--including high-performance products like fiberglass geogrid–continues to exhibit robust growth. As a critical component in infrastructure rehabilitation and heavy-duty construction, its demand is expected to grow materially because of several key variables.

Major growth drivers:Aging infrastructure reclamation: One of the major reasons behind global road repair and life extension needs. Fiberglass geogrid for asphalt mix traffic reinforcement represents a basic technology in overlay systems that effectively postpones reflective cracking, shortens repair cycles.

The Growth of Heavy Load Testing: Worldwide trade and logistics make the demands for high loads on infrastructure. Ports, container yards, and industrial facilities all rely on geogrid s high tensile parts. This stabilizes a sub-grade that would never have been given a second thought without it. It provides us with the means to distribute load to more than one place at a time, eliminates any number of trippers and obstacles, and provides another two feet (or more) worth of anchorage in our case.

· Economic Analyst of Lifecycle Expenses: In government and private construction projects, it is increasingly common to consider the cost of an entire life. By dramatically extending the life of fiberglass geogrid, now the initial material cost advantage becomes cost effective.

· Appeal in the Harshest of Environments: Superior resistance to chemical and biological deterioration enables chemical resistant geogrid to solve problems in fresh water environments, preclude microbiological damage in aggressive and challenging soils, mining operations and coastal areas.The business is moving more and more towards ever more sophisticated products. Trends include the development of fibreglass geogrids with enhanced bond qualities due to polymer coatings for superior composite actions with asphalt, as well as a growing emphasis on sustainability, and a need to validate long-term performance data according to more rigorous engineering specifications.

Technical Prowess: Production & Material Science

Fiberglass geogrid's remarkable performance is due to both its advanced material composition and the precision manufacturing process.

So What is Glass Fiber for?

Basic to its performance as a reinforcement material are the following properties of this glass fiber core: 1. Outstanding Tensile Strength: The strength-to-weight ratio of glass fibers is among the highest available, providing great reinforcement capacity. 2. High Modulus of Elasticity: This high rigidity means the geogrid supports stress with very little elongation, giving immediate support and minimizing distortion. 3. No Creep: Unlike some polymers, fiberglass does not display significant creep under sustained loads. This results in good dimensional stability and long term performance. 4. Resistance to Temperature Variation: It performs well over a wide range of temperatures and is not influenced by the high heat of asphalt laying.

Chemical Inertness—Its high-level ability to resist corrosion by most acids, alkalis and salts makes glass one of the most durable materials available for use in aggressive environment.

The Manufacturing Process:

The production of polymer coated glass fiber geogrid is complex and technology-intensive and requires several phases.

Filament Production: Molten glass is drawn into extremely fine continuous filaments.

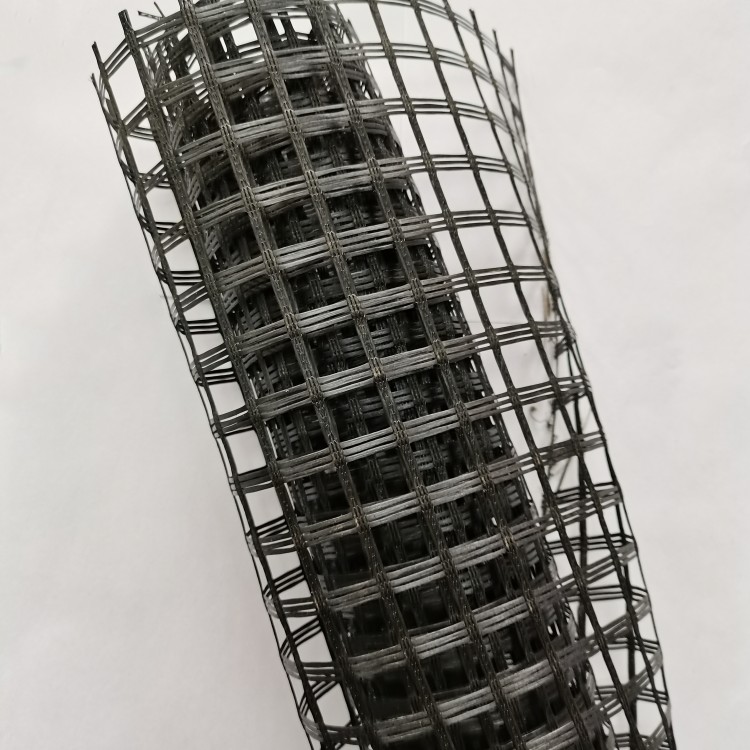

Yarn Formation & Weaving: Hundreds of filaments are bundled into yarns which are woven or knitted with special looms to give a precise grid structure at the base fiberglass geogrid mesh.

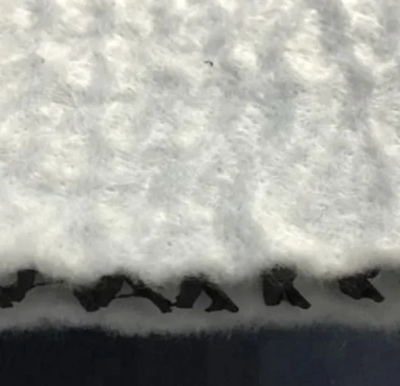

Critical Coating Application: The woven grid is "dipped" in a specially compounded liquid bitumen or similar material, this step is crucial because it protects fragile glass filaments during installation and service life; it connects fiber intersections hardening into robust integral junctions; and provides a surface that enhances binding with asphalt or soil.

Curing and Finishing: In the ovens of carefully controlled temperature, the coated grid passes to cure and solidify the coating. Then it is rolled up ready for shipment or installation as geogrid for pavement reinforcement.

Primary Applications and Engineering Benefits

Fiberglass geogrid is designed specifically for situations in which the ability to absorb tensile movement and the kind of stiff stability over time that only long-term products can give are most important.

Asphalt Pavement Reinforcement (Overlay Systems)

This is its most important application. Fiberglass geogrid, when installed between old and new overlays of asphalt, acts as a stress-absorbing interlayer

· Benefit: It absorbs and distributes tensile movements from the old pavement during longitudinal cracking, thereby postponing greatly reflective wall crack for (intercourse outer straight) life by 3-5 times at least.

Base Reinforcement for Heavy-Duty Pavements

For roads, airport runways, and industrial yards subject to extremely severe loadings, fiberglass geogrid is positioned inside or at the bottom of the base course.

Benefit: Enabling faster load distribution across weak subgrades so no individual part takes the brunt and wears out first, less rutting, smaller aggregate.grizzly etc.

Special Conditions of Soil Stabilization

For embankments, slopes, or structures where chemical resistance is a major concern, fiberglass geogrid offers long-lasting reinforcement.

Benefit: Its chemical stability means that it will last in environments as acidic, alkaline, and salty as any polyester and some polypropylene geogrids might destroy.

General Course of Installation:

The installation method changes with each usage. For asphalt resurfacing, a tack coat is sprayed on to the existing pavement, the fiberglass geogrid carpet is rolled out and pressed down, and an immediate hot mix cover coat is applied. For base reinforcement, it is laid on top of a prepared foundation with jointing as specified overlain by well-graded crushed rockfill to the prism top.

QA

Q1: What is the biggest difference between fiberglass geogrid and polyester or polypropylene biaxial geogrid?

A: The chief difference between fiberglass geogrid and polyester or polypropylene (PP) geogrid is that fiberglass has a far higher tensile modulus (stiffness) and negligible creep. While PP/polyester geogrids work well where tensile forces are restrained through soil-surface friction and particle interlock, they don't compare with fiberglass geogrid in ability to absorb forces acting away from these planes. With symptoms like stripping and crack-induced failure very similar to those in an asphalt surface reinforcement or prevention of PP/polyester geogrids in heavy field roads, users may want more assurance than this sort of performance-a greater to degree of built-in toughness.

Q2: Isn't fiberglass geogrid too brittle and hard to install?

A: Though the raw glass filaments are weak and any breakage is forthwith communicated to the final polymer coated geogrid product, it is designed for easy handling in standard practice. To protect the filaments from kinking or being cut by roadbed surfaces, the protective coating is applied.

But it should never be scraped across sharp materials or subjected to any concentrated impacts. Always follow the manufacturer's instructions about handling.

Q3: How to select the right strength and geogrid type for your construction project?

A:It varies by design. Main factors to consider include the required ultimate tensile strength (kN/m), the modulus (stiffness), and aperture size. This is determined by factors like existing pavement condition, traffic loads and subgrade quality. Always contact the geogrid manufacturers technical team and give them your project details when looking for a specific recommendation.

Q4: Can I use fiberglass geogrid on soft soil roads?

A:The traditional choice of something like a standard gravel fill mat or medium-stiffness base geogrid is not suitable for unpaved roads where large deformations occur. In very soft soils therefore, perhaps it would be better going with a polyester geogrid of high strength and well as proportionately longer extensibility to accommodate those greater deformations. Specialised analysis is vital.

Pulling It All Together: Building Resilience with Advanced Materials

Fiberglass geogrid technology's evolution is a major advance in resilience. It is able to offer long-term predictable performance in harsh conditions which means that it is not simply a material, but also a strategic investment towards asset longevity. For B2B buyers, choosing a fiberglass geogrid puts lifetime value before upfront cost.

At the selection stage, look for suppliers who can offer not just guaranteed high-quality products but also the full technical data, sound installation guidance and worldwide projects experience. With the right partner, the engineered benefits of fiberglass geogrid for road reinforcement will be fully realized on your project.

Professional Call to Action:

Choose with confidence for your next big project. Contact our engineering support team to:

· Get project-specific fiberglass geogrid recommendations and technical data sheets.

· Access case studies and reports on the performance of similar large international projects.

· Obtain samples and detailed installation guidelines customized to the specific needs of your application.

· Discuss volume pricing and logistics solutions for your global supply chain.

Visit our website or contact our experts directly to request a consultation and turn your infrastructure challenges into long-term solutions.