Composite Filter Layer

1. Integrated Filtration & Drainage Performance

Combines the functions of waterproofing, filtration and drainage in a single structure, effectively preventing soil erosion while ensuring smooth water seepage and discharge.

2. Superior Drainage Efficiency

Delivers stronger drainage capacity than traditional granular materials like sand and gravel, avoiding water accumulation and structural damage.

3. Outstanding Structural Stability

The bonded integral plate structure maintains high integrity and stability in complex geological conditions, with no risk of material separation or failure.

4. Efficient & Convenient Construction

Lightweight and ready-to-use, it simplifies construction procedures, reduces on-site processing time and significantly improves construction efficiency.

5. Wide Adaptability

Suitable for diverse civil engineering scenarios including hydraulic, transportation, municipal and construction projects, adapting to different base conditions and engineering requirements.

6. Controllable & Reliable Specifications

Available in customizable thicknesses and widths, with stable water flux and weight parameters to meet precise engineering design standards.

Introduction

A composite filter layer is a structural layer that combines multiple materials for filtration and drainage, and it is widely used in civil engineering. Below is a detailed introduction about it:

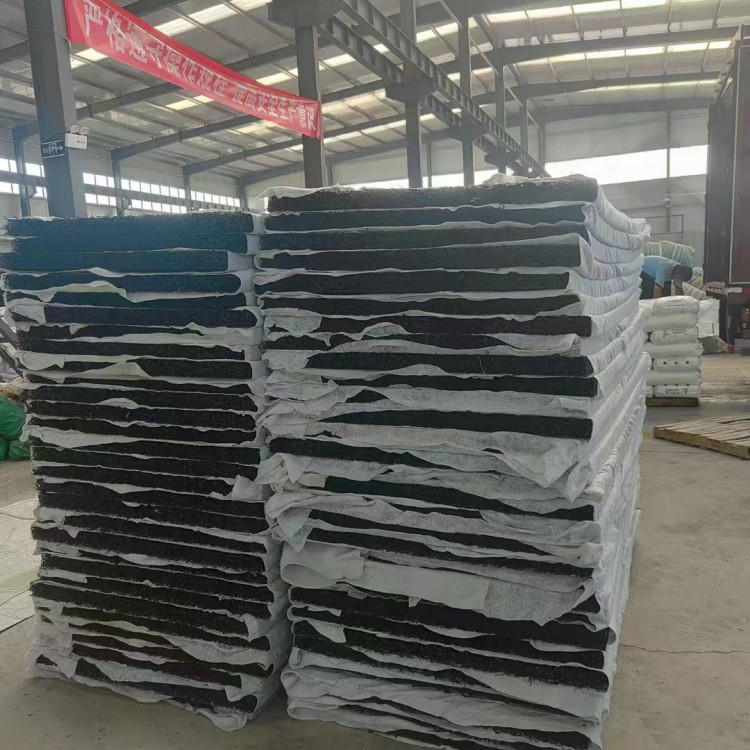

Structural Composition:

It typically consists of a waterproof layer, a filter-permeable layer, and a filter-drainage layer bonded together to form an integrated sheet-like structure. The waterproof layer is generally made of flexible film materials such as PE or PP membranes, which prevent cement slurry infiltration. The filter-permeable layer is often composed of nonwoven geotextile, serving a filtration function. The filter-drainage layer is usually made of thermoplastic synthetic resins formed into a three-dimensional mesh structure, providing excellent drainage capacity.

Performance Characteristics:

It offers high filtration efficiency, effectively preventing soil erosion and maintaining soil stability. Its drainage performance is superior, with stronger drainage capacity compared to traditional materials like gravel and sand. It is convenient for construction, simplifying processes and improving efficiency, while also being structurally stable, safe, and reliable.

Specifications and Parameters:

Common thicknesses include 10mm, 15mm, 20mm, and 30mm, with standard widths of 0.6m or 1m. Different thicknesses of the composite filter layer vary in weight and water flow capacity. For example, a 15mm thick PFF integrated composite filter layer weighs approximately 1.35 kg/m², with a water flow capacity under specific conditions reaching up to 2.72 × 10⁻³ m³/s·m.

Application Areas:

In hydraulic engineering, it can be used for the protection of dams and reservoirs. In transportation engineering, it is suitable for the drainage of roadbeds, pavements, slopes, and retaining walls in highways and railways. In municipal engineering, it can be employed for the drainage of groundwater and surface water in roadbeds, subway tunnels, and landfills. In construction engineering, it can be used for drainage, seepage prevention, and insulation in building foundations, interior and exterior walls of basements, and green roofs.

Key Construction Points:

Before construction, ensure the base surface is flat and free of debris. During installation, the composite filter layer should be laid flat and without wrinkles, and it must be tightly connected to surrounding structures. After installation, secure it with appropriate fixing tools to prevent movement or deformation.

Quality Control and Testing: To ensure the performance and durability of the composite filter layer, strict quality control measures must be implemented during production and construction. Key testing parameters include tensile strength, puncture resistance, permeability coefficient, and interface friction characteristics. Laboratory and on-site tests should confirm compliance with design specifications. For instance, the permeability coefficient should be verified under hydraulic gradients matching actual engineering conditions to guarantee effective drainage.

Maintenance and Durability: The composite filter layer is designed for long-term performance, but periodic inspections are recommended, especially in high-stress environments like slopes or heavily trafficked roadbeds. Signs of clogging, mechanical damage, or displacement should be addressed promptly. Routine maintenance may involve clearing surface debris or reinforcing connections. Under proper conditions, the service life can exceed 30 years, depending on material composition and environmental exposure.

Environmental and Economic Benefits: Compared to traditional granular drainage materials (e.g., gravel), the composite filter layer reduces material consumption and transportation costs, lowering the carbon footprint. Its lightweight nature minimizes structural load, enabling cost savings in supporting infrastructure. Additionally, by preventing soil loss and reducing water infiltration into substructures, it enhances the sustainability of engineering projects. **Innovations and Future Trends:** Recent advancements include the integration of smart sensors to monitor drainage efficiency and stress distribution in real time. Researchers are also developing biodegradable or recycled-material variants to further improve environmental performance. As urbanization and climate resilience demands grow, the application of composite filter layers is expected to expand into areas like sponge city construction and coastal erosion control.

Conclusion: The composite filter layer represents a versatile, efficient solution for modern civil engineering challenges. Its multifunctional design, coupled with ease of installation and proven performance, makes it indispensable across hydraulic, transportation, and municipal projects. By adhering to best practices in selection, installation, and maintenance, engineers can maximize its benefits while ensuring long-term structural integrity.

Customer Visit: