Fibreglass Geogrids

Exceptional Tensile Strength & Ultra-Low Elongation:This product presents high tensile strength in two directions (usually 25-120+ KN/m), with extremely small elongation rates. This ensures the product will not creep over time, and helps to guarantee uniform stress distribution under loads.

Superior Chemical & Environmental Durability:An alkali-free glass fiber core, with high detailed polymer/asphalt coating which achieves strong resistance against alkali, salt, and acid. Avoid U.V radiation, and biological corruption.In any kind of weather it can perform stably and function without change (at temperatures from -50°C to 180°C), in corrosive soil conditions or under water.Under normal conditions, its service life is more than 30 years..

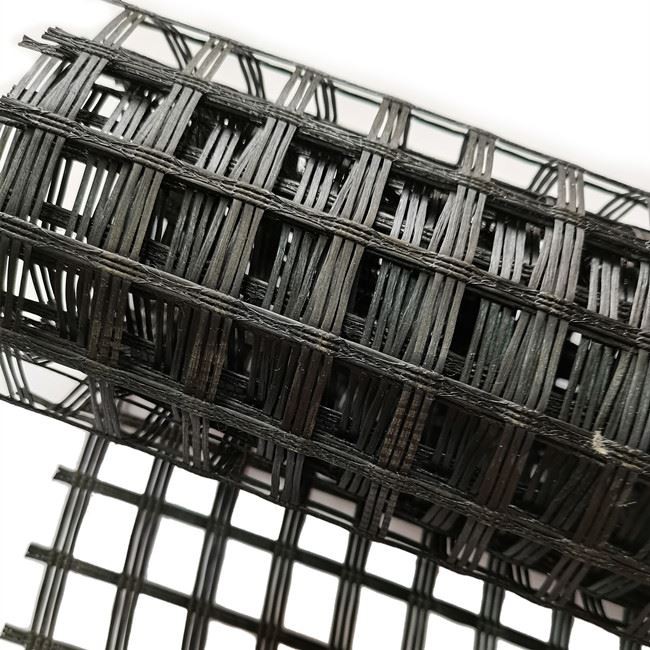

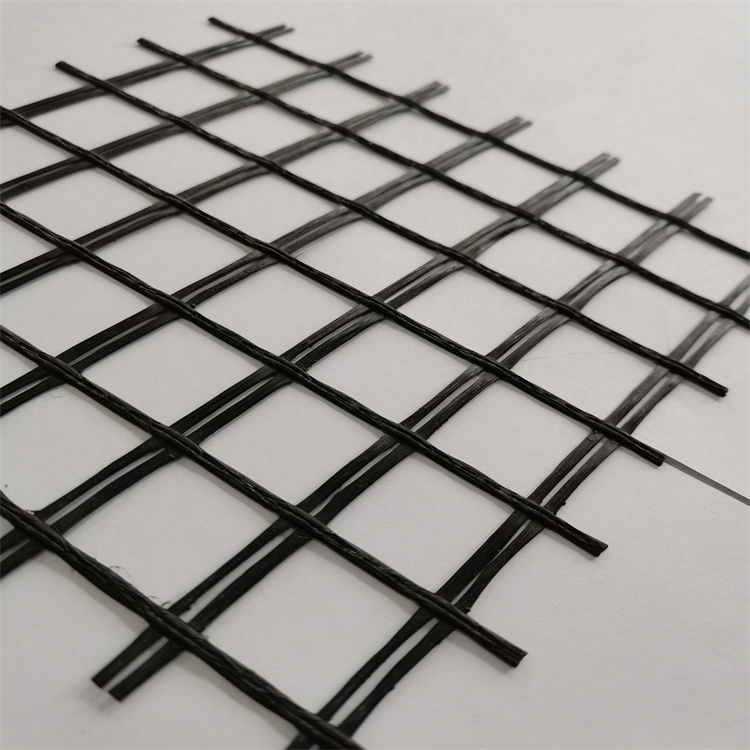

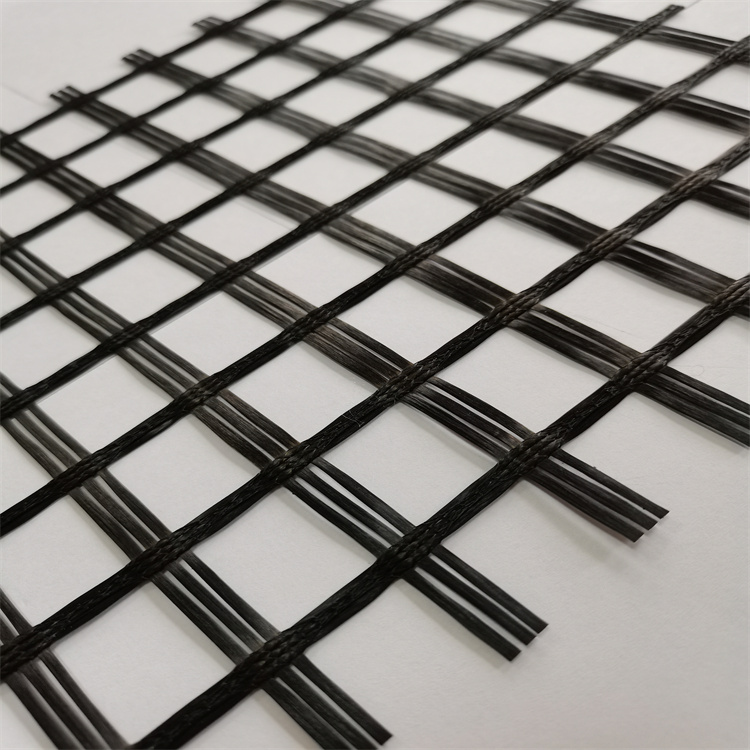

Excellent Compatibility & Aggregate Interlock:Open-mesh structure (12-50mm mesh size) enables efficient aggregate penetration, interlocking and anchorage.Modified coating ensures strong adhesion to asphalt/concrete, preventing delamination and promoting good mechanical properties with more reinforcement hybrid performance.

Cost Efficiency across Project Lifecycle:Reduction of asphalt surface layer by up to 30%.Will not affect the strength of the structure.Suppress reflective crack growth subtlely, restrain settlement of sub-base, thus making use pavements last two to three times longer than they do now; at considerable savings for long (interim) term maintenance costs and new construction style resurfacing.

Lightweight & Easy Installation:Light but firm considerable: no special equipment is needed for cutting and laying. Quick on-site construction reduces labor costs and completion time; non-woven self-adhesive types make laying even easier.

Sustainable & Eco-Friendly:Inert, non-toxic and recyclable. Its long service life means resource consumption can decrease steadily over time. It now avoids the need for replacement and repeated construction; this leads to great energy savings because waste materials are not generated or buried beneath the ground.Wherever there is long-term development into areas like this postcard we are working with local agencies at international level on behalf of public health officials some landscape architects will benefit from nature-friendly approaches that promote both environmental protection and conservation trading area Beautify Landscape Pictures Now Find!

Versatility for Multi-Scenario Applications:Throughout highway building, railway subgrade consolidation and more, it will always perform well and is a breeze to order.Cross across every part of work: no need for these varied brands or types--their efficiency is all the same.

High-strength fiberglass geogrid for road and municipal structures

Premium fiberglass geogrid is high tensile strength, alkali resistance and low elongation. It is applicable to roads, embankment reinforcement and anti-cracking even under heavy loads.

Fiberglass Geogrid – The Material of Ultimate Geosynthetic Reinforcement

In the intersection of civil engineering and infrastructure asbestos fiberglass grid, it is now a groundbreaking geosynthetic material, transforming how we strengthen pavement resistance and durability, stabilize subgrades or lengthen the life of construction projects. As the demand for infrastructural solutions which are both resilient and low-cost remains global – with the global market for glass fibre geogrid expected to hit 1.2 billion dollars by 2033, at an average annual growth rate of 5.8% – this advanced material has rapidly become an indispensable tool for engineers, contractors and project managers around the globe.

A fiberglass geo grid is a planar network structure made from high quality alkali-free glass fibre yarns. It is manufactured by advanced warp knitting techniques and coated with modified asphalt or polymer materials. Not like traditional reinforcing materials such as steel or pp (polypropylene) geo grids, fiberglass geo grids combine the innate strength of glass fibers with a stability in chemicals that only advanced coatings can offer – ensuring they last longer as well. Thanks to its unique structure, stress can be effectively transmitted at times, while preventing it in other spots. Intermeshing of the aggregate and a crack are avoided under extrusion thus making it an ideal material for road construction works to be used on the soil reinforcement layer. Also it has the potential markets in rail line projects, some water power engineering structures and coastal soft grounds.

Intended to solve the common infrastructure problems – from reflective cracking in asphalt pavements to subgrade settlement with poor soil conditions – fiberglass geogrid offers an aesthetic and environmentally friendly solution that lowers maintenance costs and extends the life of building projects. Whether it is used on new construction or old road rehabilitations, this versatile material will deliver steady performance across various environmental conditions, from temperatures to extremes.

Key features of Fiberglass Geogrids

Because each of its carefully designed characteristics is tailor made to perfectly meet the demanding needs of civil engineering projects, the superior performance of fiberglass geogrid is unmatched by any other kind of grid. All of these features guarantee that in any situation you choose to place it, whether there is water present or not. Moreover with its built-in strength accepected by some well-respected companies like Balfour Beatty Plc (UK) and Williams Advanced Engineering ltd. (UK) In terms of, but not lesser than.

Unrivalled tensile strengths and low elongation

Fibre geogrid has good performance in terms of tensile strength & transverse tensile strength and resistance to adhesion, The standard range for tensile strength is from 25 KN/m–120 KN/m or higher with economical prices. The elongation at breaking point is quite low (≤ 3-4%). So under shock loading conditions such as repeatedly dropping heavy stones on a geogrid layer of less than 5mm thick, then recovered to its original state after the shock loading has ended- its like your spine when you lift something incredibly heavy after not doing so for a long period. Unlike plastic or steel wire materials which may flow over time, the structural integrity of fiberglass geogrids will not change over time. Hence it gives long-term reinforcement without performance loss. This strength and stability enables it to distribute stress over a large area effectively, reducing point loads on pavements that lead to cracking material.

Initial success masks long-term challenges

Thanks to an alkali-free glass fiber core and a special coating, Fiberglass Geogrid can offer excellent resistance to alkali, acid, salt and all sorts of corrosive earthwork environments. It also will maintain this performance for over 30 years. Moreover due to its ability in a wide range of temperatures from 180 °C down to below-50 °C, Fiberglass geogrid can still be used under conditions which see the maximum working temperature rise well above 60 °C during asphalt paving in loud flexural environments and low-temperature conditions down to-30° C in cold regions with good results.

Best Compatibility and Interlocking Performance

Fiberglass geogrid is designed to perfectly integrate into the base materials of pavements such as asphalt and concrete. Its open mesh structure (usually 12mm×12mm to 50mm×50mm) allows aggregates to penetrate and lock in with the grating, resulting in overall mechanical security of utmost tightness For asphalt pavements, the modified asphalt coating provides strong adhesion between the grating and asphalt matrix. This prevents delamination, and ensures long-term bonding. Self-adhesive varieties also help to further simplify installation and improve interface compatibility .

Lightweight & Simple Fit

With a weight of only 100-300 g/m², the fiberglass geogrid is light and flexible, making it easy to transport, handle and install on site. It can be cut into custom sizes as needed without any specialized equipment, and installed using simple techniques such as mechanically fastening or overlap bonding (with recommended dajie width of 10cm or more). Because the material is so so versatile, it will do well no matter what kind of surface you put it on. Perfectly fitting with no gaps ensures full contact and uniform stress distribution to the substrate, also means reduced labor cost and shorter project timelines compared with traditional reinforcement methods .

Core Advantages of Fiberglass Geogrid for B2B Applications

Fiberglass geogrid offers many compelling benefits for B2B buyers in the construction, infrastructure, and engineering sectors that create value, efficiency, and project success. These benefits address key pain points such as high maintenance costs, project delays, and performance inconsistencies.

Less expensive than traditional materials, fiberglass geogrid prescription markedly cuts up-front construction costs of roads and directories.The geogrid allows for thinner asphalt layers in road construction without reducing structural integrity, saving up to 30% on material. Such low costs are especially significant.At the same time, the material’s longer life-span together with its resistance to cracks, potholes, and sub-grade settlement promises twice as long service compared without reinforced pavement, cutting the number and costs of repairs.All those precious savings are put for B2B buyers in charge of big projects, into improved profit margins and competitive quotes on materials that they pass on to the end customer.

Enhanced Structural Performance & DurabilityThe material’s stress distribution ability, crack resistance and subgrade stabilization all directly enhance infrastructural construction quality . Within asphalt concrete pavement overlays, fiberglass geogrid greatly reduces the occurrence of reflective cracks caused by temperature change and vehicle loading. Tests indicate that it has double the ability to resist cracking (in dole tests, which simulate traffic loads over pavements without reinforcement). It can also bear better fatigue and rut, keeping up performance - even where traffic is particularly heavy.For undertakings located in difficult environments, such as soft ground or by the seacoast where soils are corrosive, the high durability of this material means little change over time for practical purposes.Such resistance means that innovation is ecological for now and tomorrowAs the need for sustainable projects has become a major world-wide plank, efforts V largely consists of he serio-des need to find an environmental re-placement of traditional reinforcing materials. The material’s long life reduces the need for often rebuilding, consuming resources and producing waste. Moreover, it is inert, unpolluting and non-toxic. Hence the material does not pose any environmental risk either during its installation or subsequent use as a laying course insulation solution. Fiberglass geogrid can help reduce carbon emissions associated with recurring construction activities, in line with global sustainability objectives by prolonging infrastructural life spans.

Versatility Across Diverse Applications

Fiberglass geogrid is adaptable, suitable for all kinds of B2B applications from transportation infrastructure to river and harbor engineering. Its stable performance in different project applications means that purchasers do not need to go around constantly looking for specific materials, simplifying procurement and supply management for those that buy it in from all over the world. No matter where it is used in the engineering of roads, railroads or levee reinforcement, this material retains its basic properties, providing one kind of backing up for many needs.

Applications of Fiberglass Geogrid in Civil Engineering & Infrastructure

For countless civil engineering applications, from transportation to hydraulic and geotechnical projects, fiberglass geogrid's versatility and performance have made it a must-have. Below is where the material delivers top value in key usage areas.

Road Construction & Rehabilitation

The most common use of fiberglass geogrid is in road construction and rehabilitation. It is used for:

New asphalt pavement: Placed between the boulder layer and surfacing to strengthen load-bearing capacity and prevent rutting.

Old road retrofit: Served as an intermediate layer in asphalt overlays to suppress reflective cracks from existing concrete or asphalt pavement .

Road expansion projects: Stabilizes the connection between new and existing pavement, preventing non-uniform settlement and cracking.

Expressways: Satisfies heavy traffic loads plus varying temperature environments, ensuring long-term service life.

Railway Subgrade Stabilization

Railway installations need an extra-stable foundation or the safest and most effective operation of rail traffic cannot be assured. Fiberglass geogrid is used to reinforce railway subgrades, resulting in less settling and limiting horizontal movement. It shares out the freight that trains carry on this foundation uniformly, avoiding distortion and extending the lifespan of railway tracks. The material's resistance to dampness and corrosion also allows it to be used in railways, regardless of the environment: arid areas;p ong, secrete bag ocean .

In hydraulic projects, fiberglass geogrid is used for slope stabilization, embankment reinforcement and erosion control. With good water and chemical resistance properties, it is an ideal material for such work as:Prevention of soil erosion caused by water flow and wave action,River bank and coastal slope protection;Keeping reservoir and canal linings stable to protect against leaks and cracking,Reservoir and canal linings;Making sea wall more of a strength against tidal forces and corrosion.Seawall reinforcement.

In soft soil areas, project owners encounter significant problems with subgrade settlement. Fiberglass geogrid strengthens soft soil subgrades by improving soil bearing capacity and evenly distributing loads over the area. It is possible to speed up soil consolidation, reduce post-construction settlement and ensure a uniform distribution of stress. This application is particularly valuable in areas where weak soil foundations have been chosen for such projects as industrial parks, airport runways and residential districts.

Uses of fiberglass geogrid are extended to airports and various other sectors:A supermarket may have parking space near the front entrance for those who wish to buy their groceries later on, when it's closed;Runways at airports, where it strengthens pavement so that heavy aircraft can operate safely all year round.Airport runways.

The quality of high quality fiberglass geogrid production requires varied, complex processes to ensure consistent performance and adherence to internationally recognized standards. A simple introduction to the production system might read like this:Select high-quality tensile strength, alkali-free glass fiber yarns with excellent chemical stability as raw materials. These yarns, containing a high percentage of pure silica, are 90% and above26 composed of the material. This ensures that they will be both inert and resistant to corrosion in practical use.

For the glass fiber yarns are used to weave a mesh structure through advanced warp-knitting units. This process gives the material its directional markings, which ensures best tensile strength in both warp and weft directions. filament windingapolystyrene membrane against rain inside reservoirawashing space.

Coating : The aramid mesh is coated with carbon film or lacquer material, such as PVC or polyester. The characteristics of this layer is that it separates the glass fiber from water and Alkali corrosion materials; it can improve adhesion to other materials in the road and so enhance product service life .

At every stage of the process--pre- curing, curing and stable cure --the coating will firm up the glass fibers. Comprehensive quality inspections are carried out. These include tests for tensile strength, elongation and adhesion, ensuring conformity with international standards ( such as those from ISO, ASTM, etc.).

Finished Product Cutting & Packing: The finished fiberglass geogrid is cut into standard rolls (width: 2-4 meters; length: 50-100 meters) can also custom tailored according to the consumer 's needs Rolls are packed in moisture-proof materials to prevent damage during transportation .

FAQs about fiberglass geogrid for export merchants in China

What specifications should I choose from for my project in fiberglass geogrid?

The type of specification which your project requires depends on what type of project you are working on and how much load it will carry. Key parameters to consider include tensile strength (25-120 KN/m), mesh size (12-50 mm) and width dimensions (2-4m, 50-100m). For high-load highways with intense traffic could choose a higher tensile strength ( ≥80 KN/m ) with smaller spacing (12-25mm). For soft base soil strengthening can use a medium tensile strength ( 40-60 KN/m ) with a larger mesh size (25-50mm). Our technical team can suggest the best solution for your specific circumstances. Please give us your project specifications.

How about synthetic geogrid compare with polypropylene or steel geogrids?

Fiberglass geogrid offers several advantages: it has tensile strength and low elongation than polypropylene geogrids, lighter than steel. It's also corrosion resistant and easier to install than steel grids. Unlike steel, there is no question of rust nor any need for corrosion protection. This means lower maintenance costs. Compared to polypropylene, the material has no long-term creep and performs consistently for many years. For most civil engineering applications, fiberglass geogrid offers the best combination of attributes: strength, durability, and cost-effectiveness -- all three at once.

How does the installation process of fiberglass geogrids work?

It is simple to install and requires only minimal specialized equipment.

1.Prepare the base course: The surface should be flat and firm, with no protrusions.

2. Unroll the grid: Place the geotextile perpendicular to traffic or load.

3. Fasten the grid: Use mechanical fasteners, or offset adjacent rolls by 10-15cm (for self-adhesive types) instead.

4.Fill surface: Soon after devotional work of repairing asphalt pavements in Jinan, namely grinding away any bad places so that you get a great ljustice16 and get some goodYSQL ready-mixed plaster dropped intound the straw.

Customer Visit