Root Protection System

1.The advantages of tree root protection are multifaceted, impacting ecological health, urban sustainability, agricultural productivity, and infrastructure preservation. Here’s a structured overview of key benefits:

2. Economic and Regulatory Compliance

- Long-Term Savings

Preventing root-related infrastructure damage (e.g., £20,000 fines in the UK for TPO violations) and reducing replanting costs outweighs upfront protection investments.

- Regulatory Adherence

Compliance with standards like ISA’s Root Protection Zones (RPZs) and Tree Protection Orders avoids legal penalties while ensuring sustainable urban planning.

3. Technological and Innovative Gains

- Precision Management

IoT sensors (e.g., MoisturePoint) and 3D-printed root scaffolds optimize resource use (water, nutrients) and restore degraded soils, increasing root penetration by 40% in contaminated sites (Netherlands).

- Sustainable Practices

Biodegradable barriers (PBAT/PLA films) and air pruning reduce plastic waste, aligning with circular economy goals.

Tree root protection is a strategic investment that balances ecological health, urban functionality, and economic efficiency. By safeguarding root systems, societies enhance tree resilience, protect infrastructure, and foster sustainable environments—benefits that resonate across agricultural, urban, and natural landscapes.

Introduction

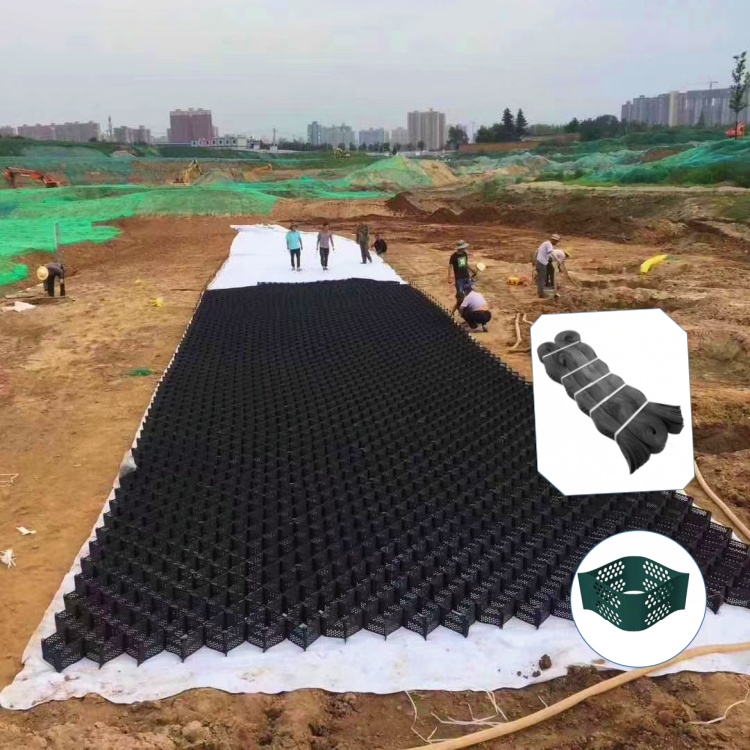

Tree Root Protection (made from high-density polyethylene) is a three-dimensional cellular confinement system (also known as CCS) used in civil engineering and geotechnical applications. This class of geosynthetic structures were primarily designed for soil stabilization, erosion control, and load support. Tree Root Protection should be calculated during the planning stages of a project before any construction work begins to avoid loss or damage to trees within proximity of the construction site. A tree survey should be conducted by a qualified Arboriculturist or Tree Consultant.

Feature

Economic

Eco- friendly

Quick, efficient and safe installation

Extremely high strength

Application Installation

Removal of floor vegetation which include turf can be eliminated the use of hand tools.

No topsoil have to be excavated or removed.

The stabilising geogrid or geocomposite have to be laid at once over the soil.

Edge boards may additionally be used to comprise the subbase and supply aspect restraint. These will be pegged in location with timber stakes.

The subbase fabric ought to be positioned by way of hand or by means of light-weight tracked plant. The subbase have to be cascaded ahead onto the geogrid with the tracked plant running solely on pinnacle of the positioned subbase. The preliminary layer thickness will be usually 150mm.

Tracking over through the light-weight plant will facilitate the combination interlock with the geogrid to set up the stabilised layer even as minimising the compaction of the soil below.

A remaining roll with a small non-vibrating curler will company the surface.

Parameters

Item | Property | Units | Value | |

Material | Polymer Density | g/cm3 | 0.94 | |

Carbon Black Content | % | 2.0 | ||

Oxidative Induction Time | Min | 20 | ||

Low Temperature Brittleness | ℃ | ≤-50 | ||

Vicat softening temperature | ℃ | ≥112 | ||

Environment Stress Crack Resistance F50 | hours | ≥800 | ||

Strip Properties | Sheet Thickness | mm | 1.1/1.2/1.5 | |

Sheet Tensile Strength | Mpa | ≥20 | ||

Sheet Surface | / | Smooth/Textured | ||

Color | / | Black/Yellow/Green | ||

Cell Depth | mm | 50/75/100/150/200/250 | ||

Seam Properties | Seam Peel Strength | N/10cm | ≥1000 |

The Lab

Inventory

Customer Visit