Geocell Erosion Control

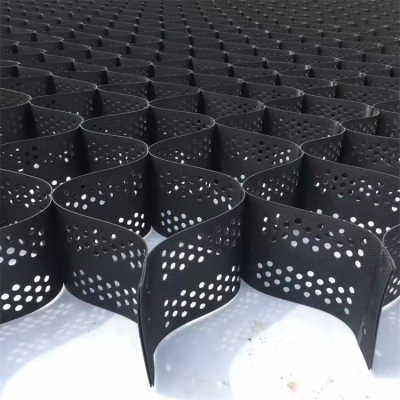

Honeycomb HDPE geocell technology represents the latest advancement in green ecological slope protection systems. It combines eco-friendliness, construction efficiency, cost-effectiveness, low maintenance, durability, and seamless integration with traditional engineering methods. Widely adopted in slope ecological protection and vegetation restoration projects across mining, transportation, water conservancy, and municipal engineering, it has become a cornerstone of sustainable infrastructure development.

Introduction

The Army Corp of Engineers invented 3D geocelluar grids in the 1970’s. The geocell ground grid was designed for quick installation on beaches for amphibious beach assaults. It could be stored and moved in a very compact form, expanded and filled with sand, and ready at an instant for supporting vehicles, which would otherwise get stuck in the sand. The grids were also used extensively in Desert Storm. Soldiers would spread the grids out in the desert, fill cells with sand, and drive tanks and trucks on them. They would even land planes on them! The grids could easily be removed when no longer needed.

Feature

Economics

Less land acquisition, excellent structure, less labor and materials, compact and light, less transportation, short construction period, low labor and maintenance

Ecological and environmental benefits of low quality fillers available at low prices

Ecology

98% of the green area is covered by local vegetation

Combination and matching are conducive to growth

Environment protection

Water soluble hazardous substances can be recycled and local filler

Reproducing natural landform and functions, preventing and controlling various environmental problems

Quick

Long, compact, light and labor-saving construction season

Simple construction, quick start, and fast continuous collaborative work

Excellent quality

High performance polymer composites with flexible and stable structure resist erosion and sedimentation

systematization

New material+four-dimensional nest room standard

Special accessories+geosynthetics integrated application

Value service improves engineering performance

Application

1. Gravity Retaining Eco-Walls:

Honeycomb geocells form a robust external wall surface from bottom to top according to dimensional requirements, tightly integrating with backfill soil to create a unified structural system. In scenarios where traditional gravity structures are impractical, geocell fill materials can be sourced locally, significantly reducing project costs.

2. Comprehensive River/Lake Bank Slope Management:

The three-dimensional structure of honeycomb geocells enhances fill strength, effectively prevents soil erosion, increases load-bearing capacity, and substantially lowers construction costs for bank slope remediation. It supports ecological restoration and protection of river and lake shorelines.

3. Stabilization of Various Soil Subgrades:

Honeycomb geocells are highly effective for:

- Cut-and-fill subgrades,

- Subgrades in sandy desert areas,

- Reinforced backfill behind abutments,

- Subgrades in permafrost regions,

- Treatment of collapsible loess subgrades,

- Stabilization of saline soil and expansive soil subgrades.

By leveraging vertical lateral confinement to achieve reinforcement effects, they resolve uneven settlement in roadbeds. In sandy areas, they restrict lateral movement of loose fill, ensuring subgrade stiffness and strength. In permafrost zones, their unique vertical reinforcement and holistic lateral confinement guarantee subgrade stability.

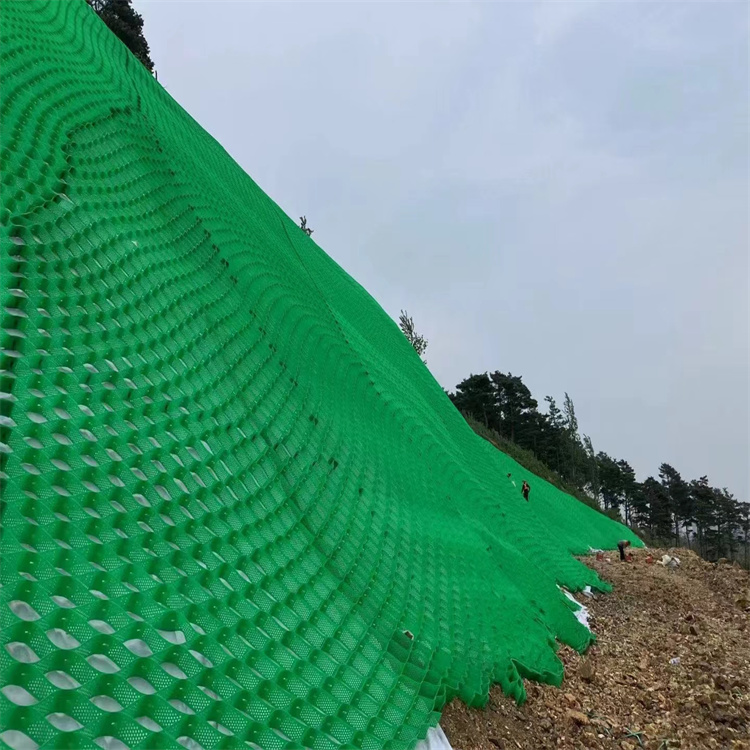

4. Slope Ecological Protection and Vegetation Restoration:

For slope ecological protection and vegetation recovery, honeycomb geocell systems are laid on slopes and filled with suitable planting soil. Vegetation such as grass, flowers, and shrubs is planted to stabilize slope soil, prevent erosion, and achieve greening and aesthetic enhancement.

As vegetation grows, plant roots interweave with the geocells and soil, forming a reinforced composite structure that further enhances slope stability. The vegetation also improves ecological conditions, boosts biodiversity, and contributes to ecosystem balance and recovery.

Parameter

Item | Property | Units | Value | |

Material | Polymer Density | g/cm3 | 0.94 | |

Carbon Black Content | % | 2.0 | ||

Oxidative Induction Time | Min | 20 | ||

Low Temperature Brittleness | ℃ | ≤-50 | ||

Vicat softening temperature | ℃ | ≥112 | ||

Environment Stress Crack Resistance F50 | hours | ≥800 | ||

Strip Properties | Sheet Thickness | mm | 1.1/1.2/1.5 | |

Sheet Tensile Strength | Mpa | ≥20 | ||

Sheet Surface | / | Smooth/Textured | ||

Color | / | Black/Yellow/Green | ||

Cell Depth | mm | 50/75/100/150/200/250 | ||

Seam Properties | Seam Peel Strength | N/10cm | ≥1000 |

Test Machines

Customer visit