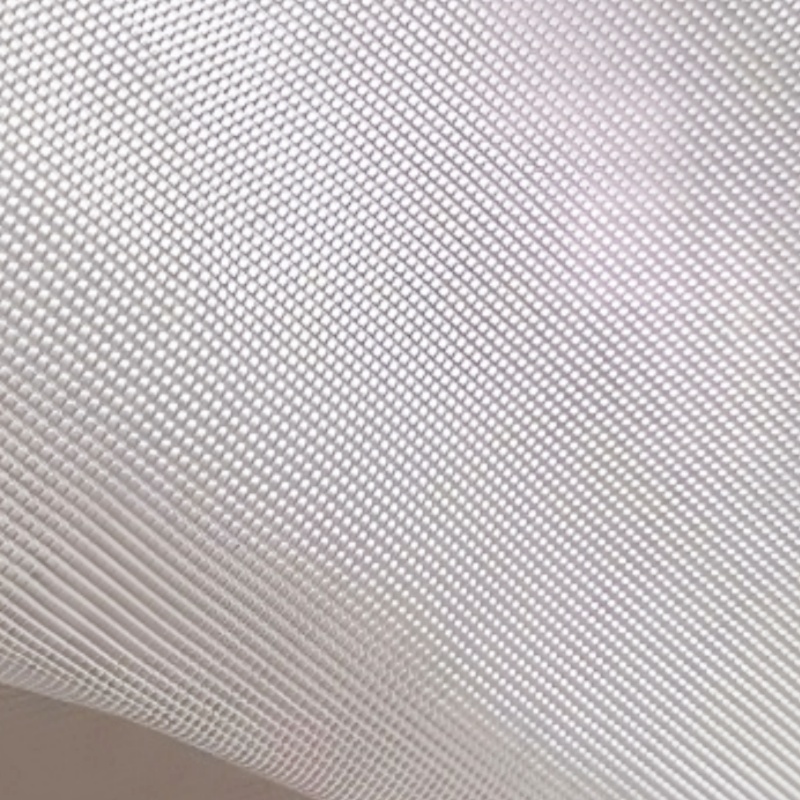

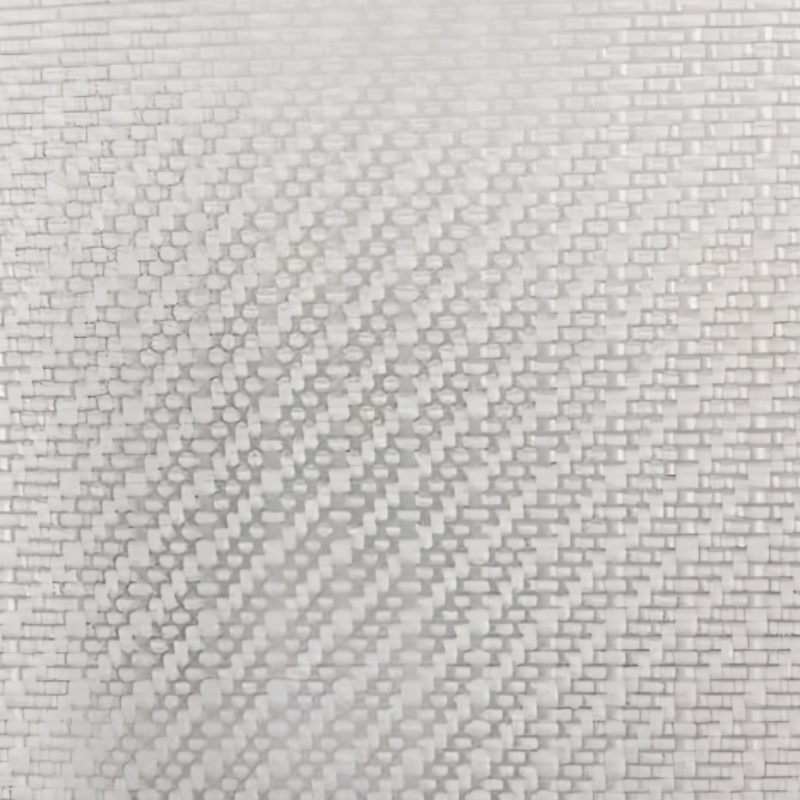

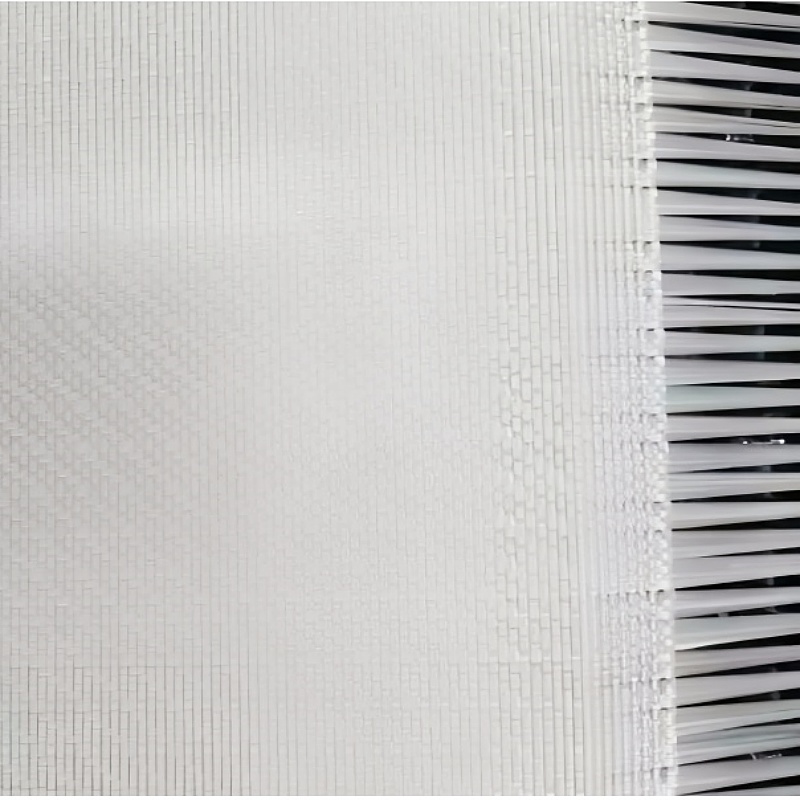

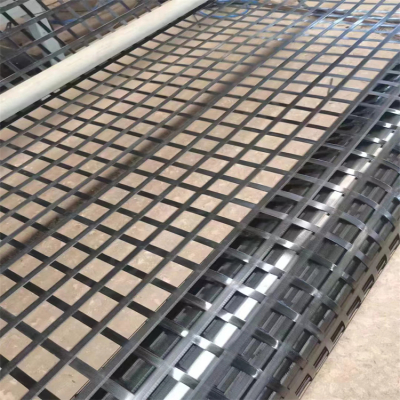

Woven Geotextile

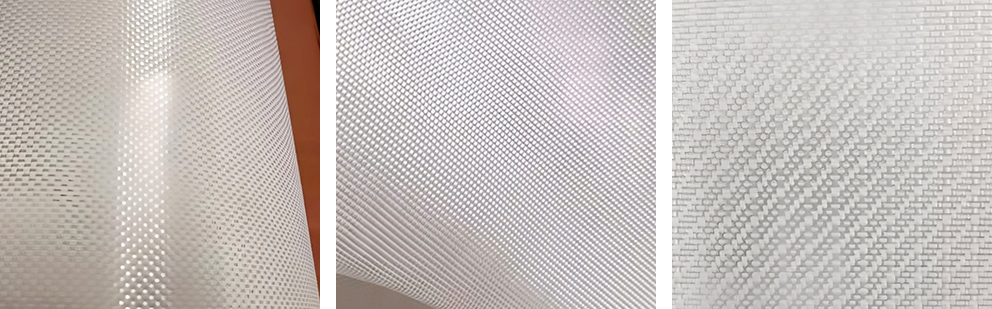

Filament woven geotextile utilizes long fiber materials, commonly polyester (PET) . We employ processes such as spunbonding, needle punching, or thermal bonding to manufacture the Long Fiber Geotextile. Compared to the Short Fiber Geotextile, the Long Fiber Geotextile has longer fiber lengths ranging from a few centimeters to several tens of centimeters, providing higher strength and tensile properties. It performs exceptionally well in applications such as soil separation, filtration, and reinforcement. Whether it’s soil consolidation, riverbank protection, or geotechnical engineering, our Long Fiber Geotextile offers reliable solutions.

Introduction:

Filament Nonwoven Geotextiles ) are made from 100% polyester continuous filaments, offering exceptional filtration, separation, and reinforcement capabilities. These needle-punched nonwoven geotextiles provide superior strength and durability, making them ideal for applications such as soil stabilization, erosion control, and drainage.

Feature:

1. Resistant to stretch, tear, bursting and puncture, high mechanical strength

2. Excellent extension performance, quick stress spreading and transmission, uniformly distribute the stress.

3. Large abrasion coefficient, less sliding during construction

4. Good chemical resistance.

Parameters:

No. | Item | Value | ||||||||||

140 | 200 | 260 | 300 | 340 | 460 | 530 | 600 | 680 | 700 | 950 | ||

1 | Nominal strength Kn/m | 35 | 50 | 65 | 75 | 100 | 120 | 140 | 160 | 180 | 200 | 250 |

2 | Breaking strength in MD KN/m ≥ | 35 | 50 | 65 | 75 | 100 | 120 | 140 | 160 | 180 | 200 | 250 |

3 | Breaking strength in CD KN/m ≥ | 0.7 tims of breaking strength in MD | ||||||||||

4 | Nominal elongation % ≤ | 35 in MD,30 in CD | ||||||||||

4 | Tear strength in MD and CD KN ≥ | 0.4 | 0.7 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | 1.9 | 2.1 | 2.3 | 2.7 |

6 | CBR mullen burst strength KN ≥ | 2.0 | 4.0 | 6.0 | 8.0 | 9.5 | 13.0 | 15.5 | 18.0 | 20.5 | 23.0 | 28.0 |

7 | Sieve size O90 mm | KX(10-2-10-5) K=1.0-9.9 | ||||||||||

8 | Width variation % | -1.0 | ||||||||||

9 | Unit weight variation % | -5 | ||||||||||

10 | UV Resistance % ≥ | 70 | ||||||||||

Application:

1. Filtration

When water passes from a fine-grained to a coarse-grained layer, non-woven geotextiles can retain fine particles well. Such as when water flows from a sandy soil into a geotextile wrapped gravel drain.

2. Separation

To separate two layers of soil with different physical properties, such as the separation of road gravel from soft sub-base materials.

3. Drainage

To drain liquid or gas from the plane of the fabric, which leads to draining or venting of the soil, such as the gas vent layer in a landfill cap.

4. Reinforcement

To improve the load bearing capacity of a specific soil structure, such as the reinforcement of a retaining wall.

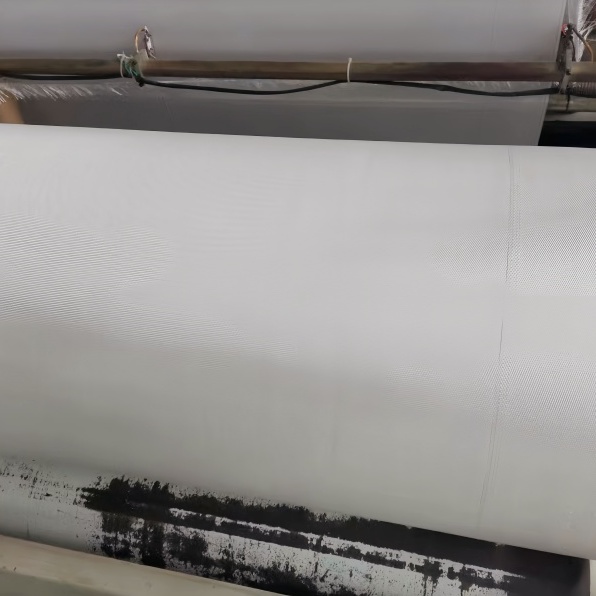

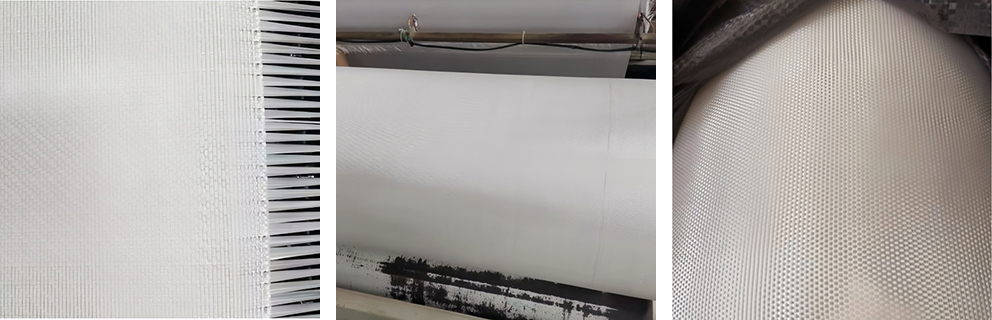

Production Line:

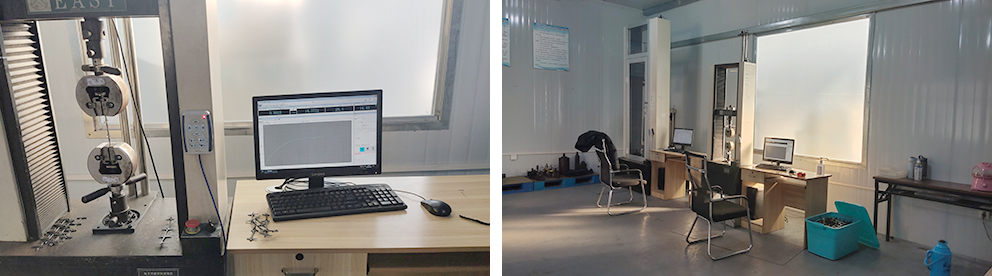

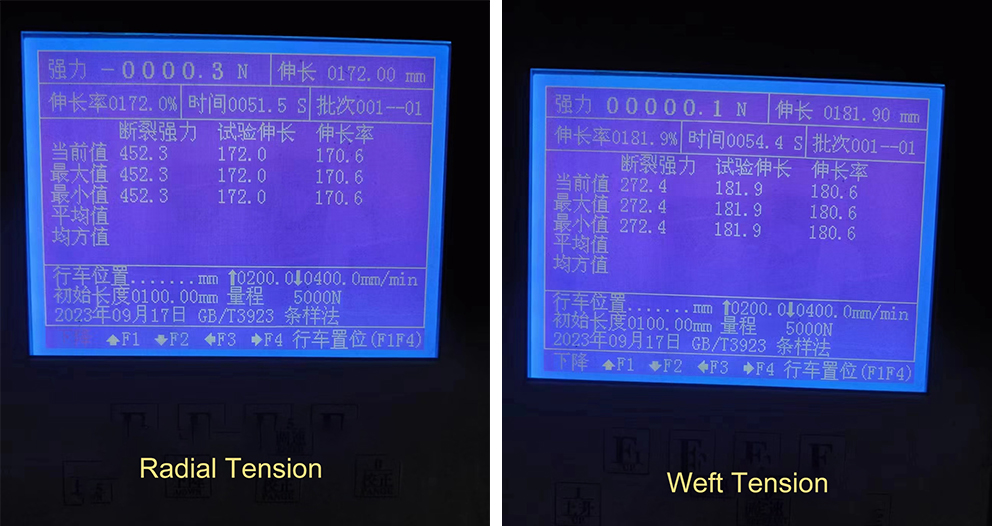

Test Machine:

Warehouse:

Shippment:

Customer Visit: