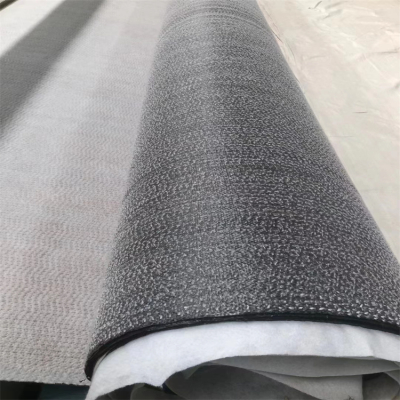

HDPE Geomembrane

High-density polyethylene (HDPE) geomembrane liners have become an indispensable material for environmental protection and containment applications. This comprehensive guide will explore everything you need to know about these durable and versatile liners.

An HDPE geomembrane is an essentially impermeable liner composed of high-density polyethylene polymer. These liners are used for geotechnical and environmental engineering projects that require containment and protection from contamination.

HDPE geomembranes are engineered with custom formulations that provide strength, flexibility, and chemical resistance. The liners are manufactured in long rolls and installed on site as a barrier layer for containment or to prevent the migration of contamination.

Introduction:

An HDPE geomembrane is an essentially impermeable liner composed of high-density polyethylene polymer. These liners are used for geotechnical and environmental engineering projects that require containment and protection from contamination.HDPE geomembrane liner is the preferred product for lining projects. HDPE liner is resistant to many different solvents and are the most widely used geomembrane liner in the world. Although HDPE geomembrane is less flexible than LLDPE, it provides higher specific strength and can withstand higher temperatures. Its exceptional chemical and ultraviolet resistance properties make it an extremely cost-effective product.

Parameter:

Thickness | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | |

Density g/m2 | ≥0.94 | ≥0.94 | ≥0.94 | ≥0.94 | ≥0.94 | ≥0.94 | ≥0.94 | |

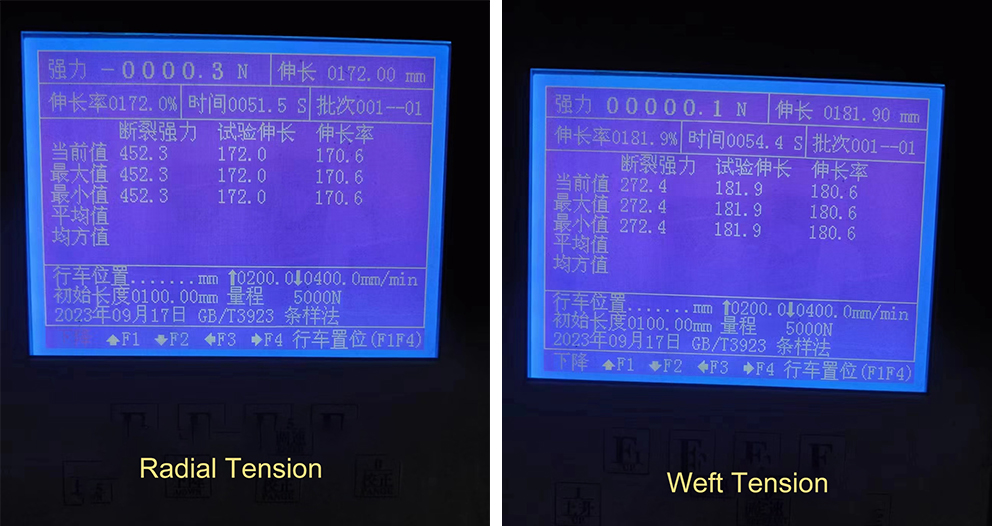

Tensile yield strength (N/mm) | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 | |

Tensile breaking strength (N/mm) | ≥20 | ≥27 | ≥33 | ≥40 | ≥53 | ≥67 | ≥80 | |

Bongation at yield(%) | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 | |

Elongation at break(%) | ≥700 | ≥700 | ≥700 | ≥700 | ≥700 | ≥700 | ≥700 | |

Tear resistance(N) | ≥93 | ≥125 | ≥160 | ≥190 | ≥250 | ≥315 | ≥375 | |

Puncture strength(N) | ≥240 | ≥320 | ≥400 | ≥480 | ≥640 | ≥800 | ≥960 | |

Tensile load stress cracking | ≥300 | ≥300 | ≥300 | ≥300 | ≥300 | ≥300 | ≥300 | |

Carbon black content(%) | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 |

Feature:

Good physical and mechanic performance

High tearing resistance, strong deformation adaptability

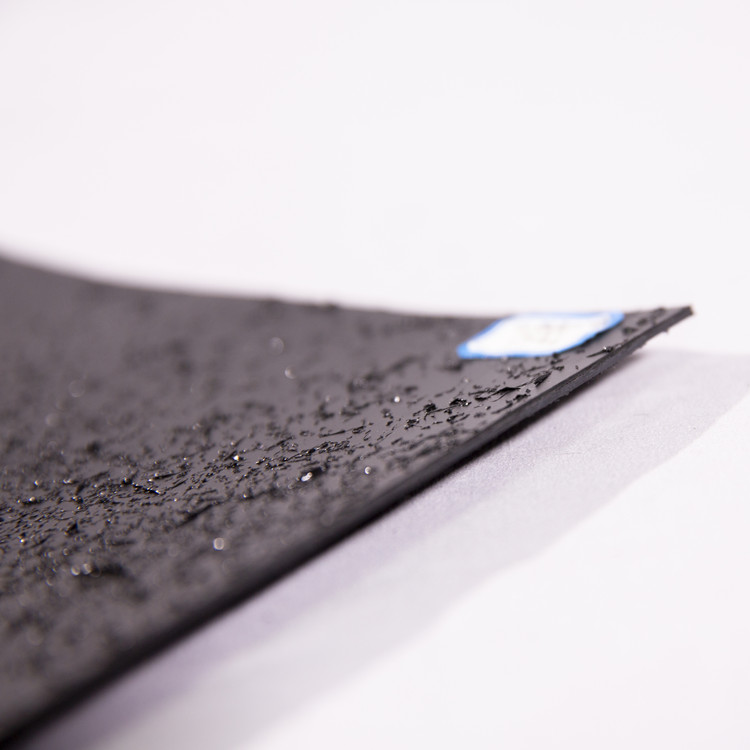

Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance

Good adaptability to high and low temperature, non-toxicity, long service life

Good waterproof, drainage, anti-seepage and damp proof effects

Complete width and thickness specifications, low cost and easy installation.

Application:

1.Irrigation ponds, canals, ditches & water reservoirs

2.Mining heap leach & slag tailing ponds

3.Golf course & decorative ponds

4.Landfill cells, covers, & caps

5.Wastewater lagoons

6.Secondary containment cells/systems

7.Liquid containment

8.Environmental containment

9.Soil Remediation

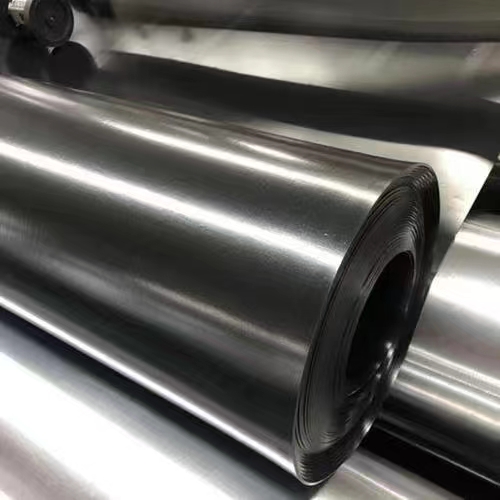

Production Line:

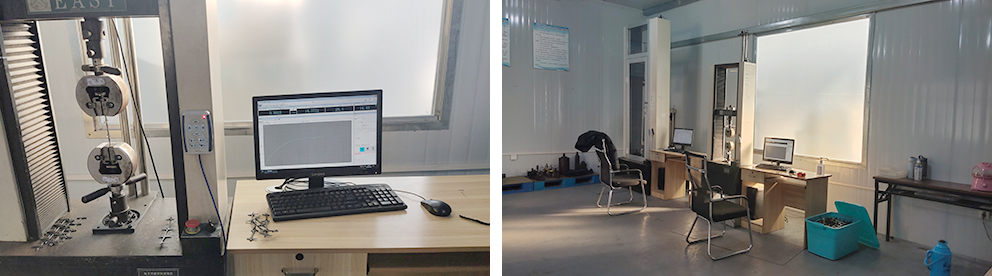

Test Machine:

Warehouse:

Shippment:

Customer Visit: