Geosynthetics Clay Liner

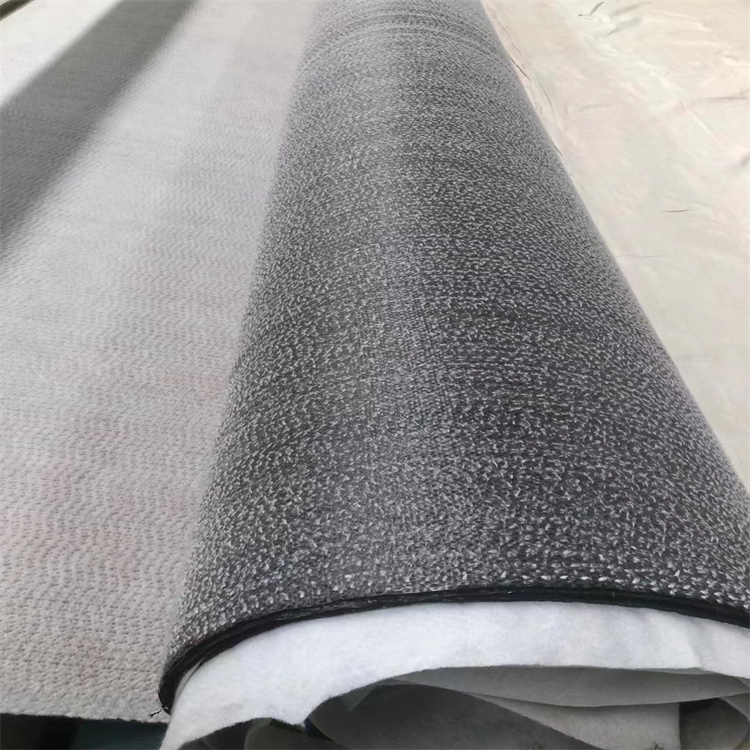

A general GCL construction would consist of two layers of geosynthetics stitched together enclosing a layer of natural or processed sodium bentonite. Typically, woven and/or non-woven textile geosynthetics are used, however polyethylene or geomembrane layers or geogrid geotextiles materials have also been incorporated into the design or in place of a textile layer to increase strength.

Introduction:

Geosynthetic clay liners (GCLs) are factory manufactured hydraulic barriers consisting of a layer of bentonite or other very low-permeability material supported by geotextiles and/or geomembranes, mechanically held together by needling, stitching, or chemical adhesives. Due to environmental laws, any seepage from landfills must be collected and properly disposed of, otherwise contamination of the surrounding ground water could cause major environmental and/or ecological problems. The lower the hydraulic conductivity the more effective the GCL will be at retaining seepage inside of the landfill. Bentonite composed predominantly (>70%) of montmorillonite or other expansive clays, are preferred and most commonly used in GCLs.

Feature:

Self-healing and self-seaming - Sodium bentonite is a naturally occurring clay with a high affinity for water. When hydrated, sodium bentonite swells up to 15 times its original volume. This provides the ability to seal around penetrations, self-heal punctures, and self-seam at the overlaps.

Better hydraulic performance - GCLs have a total thickness of less than one inch and provide better hydraulic performance than several feet of compacted clay. A fully hydrated GCL typically has a permeability of 5 x 10-9 cm/sec, approximately 20 times lower than a typical compacted clay liner permeability.

Resistant to varying weather conditions - GCLs are less likely to be impacted by freeze-thaw or desiccation-rewetting cycles. Freeze-thaw cycles frequently cause compacted clay liners to crack and lead to increased leakage. A geosynthetic clay liner provides consistent performance and is not subject to performance decreases resulting from varying moisture content, density, or clay content, like compacted clay liners.

Ease of installation and increased air space - GCLs are an environmentally friendly alternative to clay liners because they require significantly less installation effort than a compacted clay liner. One truckload of GCL is equivalent to 150 truckloads of compacted clay, thereby using up fewer natural resources. When a GCL is used in place of a thicker compacted clay liner it also takes up less air space, which leaves more room for waste.

Parameters:

Property | Test Method | Unit | Value |

Geotextile layers: | |||

Cover layer | |||

Geotextile type | Polypropylene nonwoven | ||

Mass per unit area | ASTM D 5261 | g/m2 | ≥220 |

Carrier layer: | |||

Geotextile type | Polypropylene woven | ||

Mass per unit area | ASTM D 5261 | g/m2 | ≥130 |

Bentonite layer: | |||

Type | Natural Sodium bentonite | ||

Mass per unit area | ASTM D 5993 | g/m2 | ≥4200 |

Swell Index | ASTM D 5890 | ml/2g | ≥24 |

Fluid Loss | ASTM D 5891 | ml | ≤18 |

Water Content | DIN 18121(5hrs, 105) | % | 10* |

Geosynthetic Clay Liner: | |||

Mass per unit area | ASTM D 5993 | g/m2 | ≥4500 |

Thickness | ASTM D 5199 | mm | 6.0 |

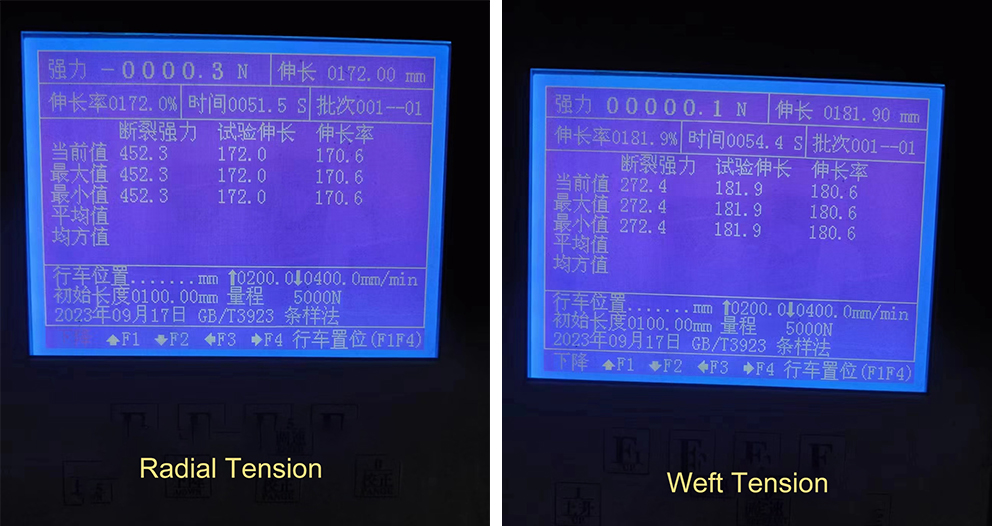

Max. tensile strength | ASTM D 4595 | Kn/m | 14, Machine Direction 12, Cross Machine Direction |

Elongation at break | ASTM D 4595 | % | 10.0 |

Max. Peel strength | ASTM D 6496 | N/10cm | ≥60 |

Peel strength | ASTM D 6496 | N/m | ≥360 |

Permeability/Hydraulic Conductivity | ASTM D 5887 | M/s | ≤2×10-11 |

Index Flux | ASTM D 5887 | M3/m2.s | ≤5×10-9 |

Puncture force | EN ISO 12236 | N | 2400 |

Application:

1.Golf course ponds.

2.Stormwater management ponds.

3.Recreational ponds.

4.Landfill cap closures / base liner.

5.Dams/dikes.

6.Vertical trench cutoff Barrier.

7.Groundwater protection cover.

8.Environmental protection barrier under roads and railways.

9.Secondary containment for above ground tanks.

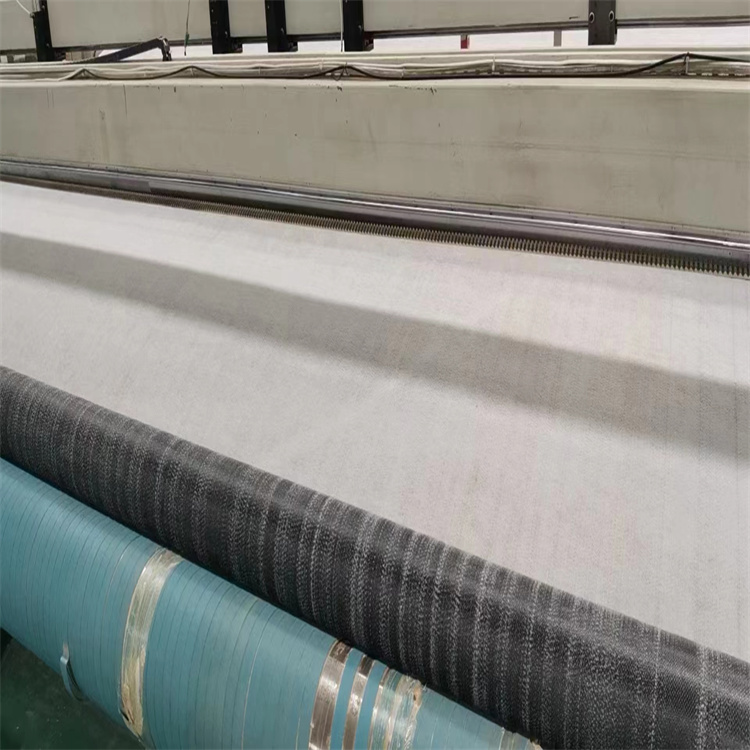

Production Line:

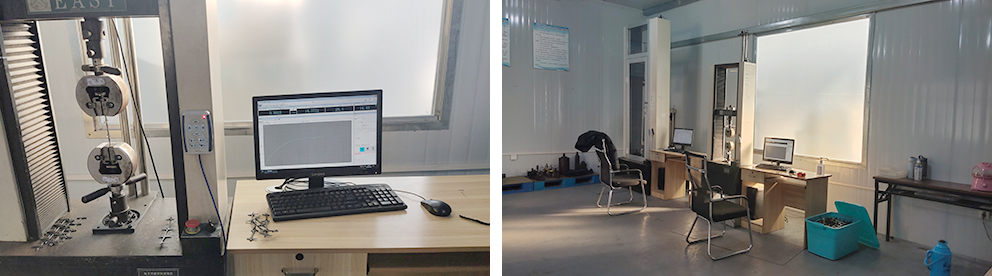

Test Machine:

Warehouse:

Shippment:

Customer Visit: