PCA Geocell

1. PCA Geocell is an ideal solution for load support and erosion control.

2. It enhances soil stability and erosion resistance by using a structural system with key components like anchor bolts, reinforced belts, and filling material.

3. Geocell can be used to create green-faced retaining walls, offering an aesthetically pleasing option.

4. It is versatile and effective for various applications, including ground stabilization, slope protection, retaining walls, and channels.

Introduction:

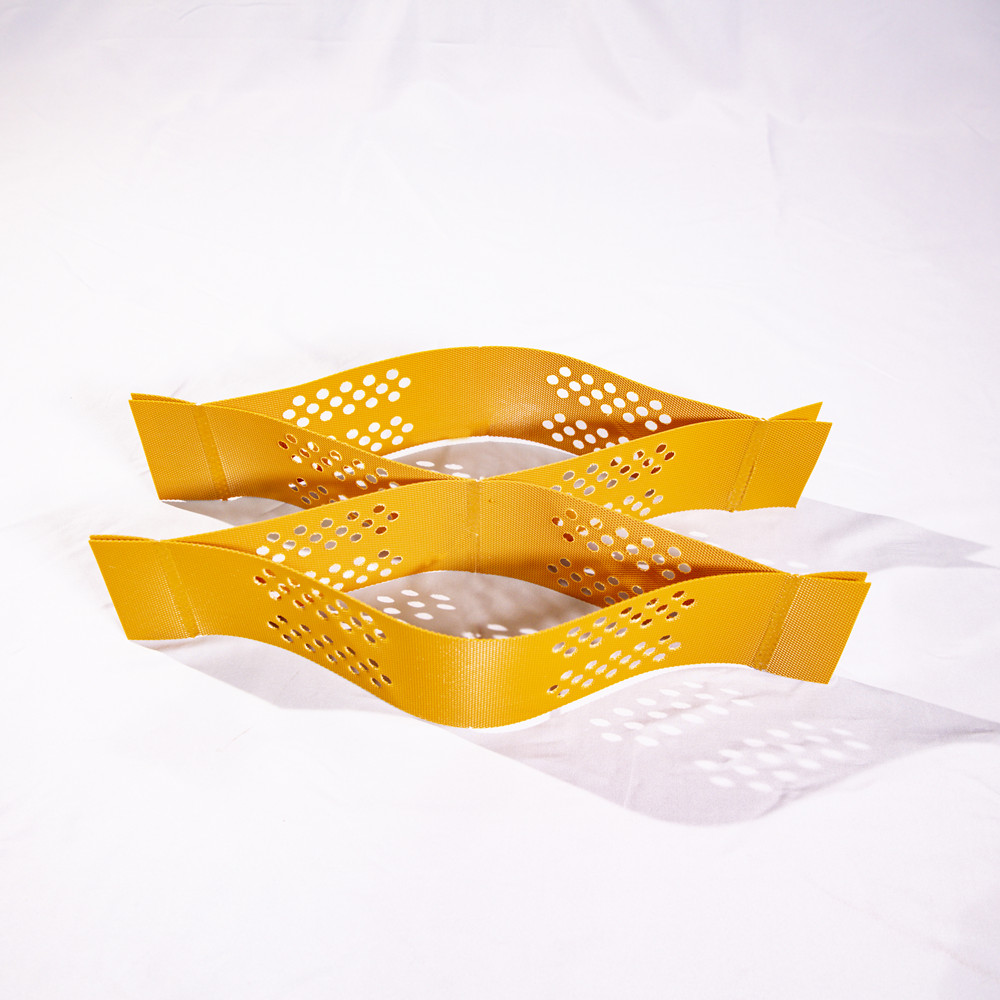

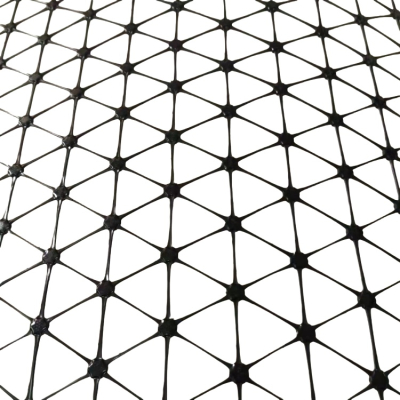

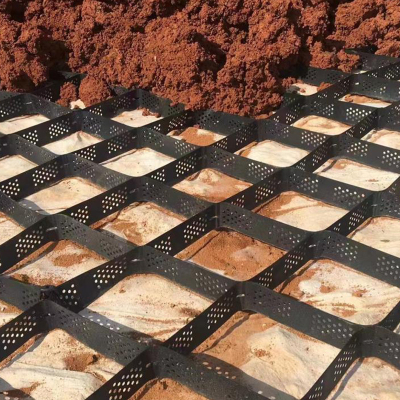

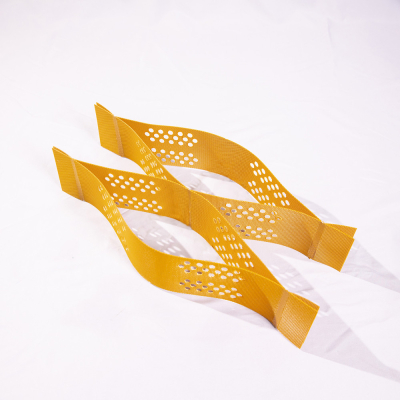

PCA Geocell is a three-dimensional cellular confinement system.It is manufactured from Polymer nano-composite alloy (PCA) strips that are ultrasonically welded together to create a strong, lightweight expandable panel.

Polymer materials formed by polyester / polyamide nanofibers dispersed within the vinyl matrix.

Initially developed by the US Army Corps of Engineers to construct unpaved roads over weak ground, it dramatically improves the performance of infill materials across a range of applications.

Geocell confines and reinforces vegetation on steep slopes by increasing the soils natural resistance to erosion and protects the root zone layer during germination.

Its' unique hoop strength and interconnecting cell walls form a durable composite mattress that can be filled with common materials. The perforated cell walls encourage lateral drainage and frictional interlock, increasing the structural performance of the system.

A structural system composed of PCA geotechnical chamber, connection key, anchor bolt, reinforced belt, filling material and surface artificial vegetation to enhance soil stability and improve the overall ability of erosion resistance, etc.

PCA Geocell is the ideal solution for the most demanding load support and erosion control applications. Green faced retaining walls can be constructed using geocell, forming a more aesthetically sympathetic solution for retaining applications. Extremely versatile and adaptable, geocell provides effective and economical solutions in a wide variety of applications including ground stabilization, slope protection, retaining walls and channels.

Parameter:

Project | Performance index | ||||

A class | B class | C class | D class | ||

Sheet yield strength-not punched, kN / m | ≥ | 29 | 32 | 35 | 38 |

Sheet yield strength-punch, kN / m | ≥ | 23 | 28 | 31 | 33 |

Weld strength, kN / m | ≥ | 23 | 28 | 31 | 33 |

ash content,% | ≤ | 3 | 3 | 3 | -- |

Long-term thermal resistance to mechanical performance loss rate,% | ≤ | 10 | 15 | 10 | 10 |

Long-term loss rate of photo-mechanical property resistance,% | ≤ | 25 | 30 | 30 | 25 |

Feature:

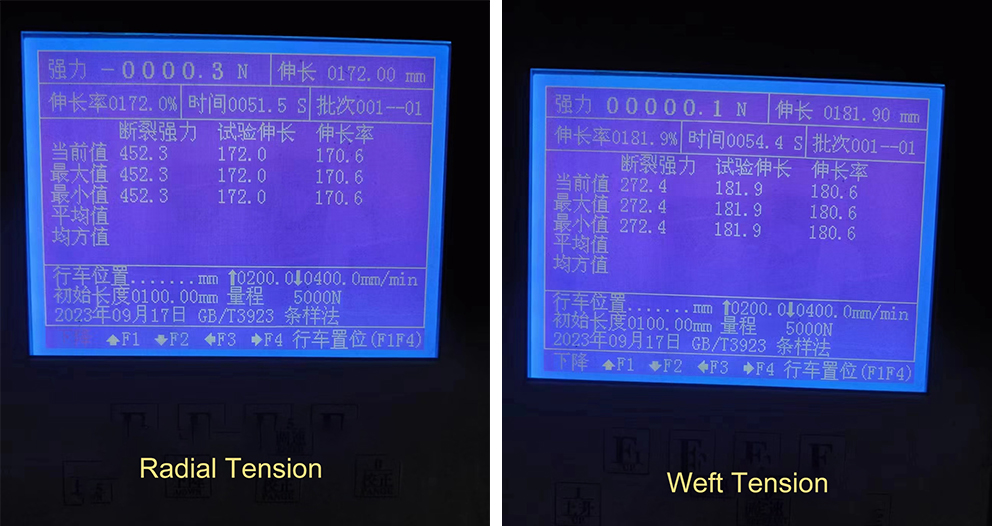

➢High tensile strength and peeling strength

➢Light weight, wear-resistant, chemical stability, light oxidation aging, anti-acid/alkali corrosion, applied to different geological conditions, such as saline soil, desert, etc.

➢ Wide temperature range, high tensile strength, good rigidity and toughness, good load capacity and anti-erosion ability.

➢ Size is relatively stable, change the height and welding distance can meet the needs of different projects.

➢ Retractile, easy to transport.

➢ Easy to use, can use the local materials and achieve rapid construction, reduce construction costs.

Application:

• Slopes • Channels • Vegetative soil filled channel • Aggregate filled channel • Concrete filled channel • Embankments • Retaining walls • River banks

Production Line:

Test Machine:

Warehouse:

Shippment:

Customer Visit: