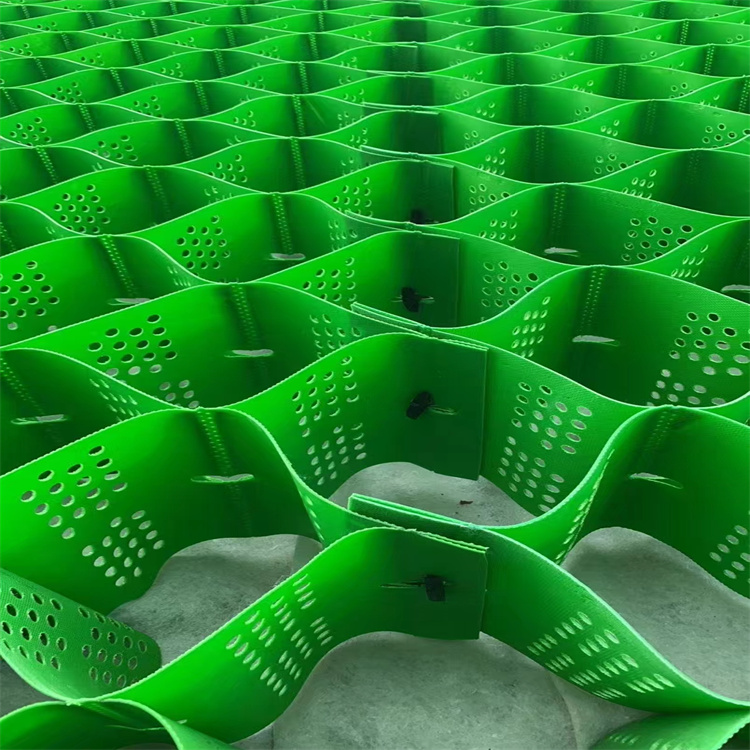

Geocell

The advantages of geocells

Geocells are a network of cellular structures formed by strong welding or riveting of high-strength HDPE or PP copolymer materials, with the following advantages:

- High lateral restraint and anti-slip property

The three-dimensional structure of geocells can provide strong lateral restraint to the filler, effectively preventing the lateral movement and sliding of filler particles, enhancing the stability of subgrades or slopes, and is particularly suitable for steep slopes and other areas prone to sliding.

- Good flexibility and adaptability

Geocells have a certain degree of flexibility and can adapt to changes in different terrains. Whether on soft soil foundations or complex mountainous terrains, they can better fit the ground and exert their reinforcement effect, reducing engineering problems caused by topographic differences.

- Improved foundation bearing capacity

By evenly distributing the load over a larger area, geocells can effectively reduce the pressure per unit area on the foundation and improve the bearing capacity of the foundation. This can reduce the cost and difficulty of foundation treatment, making engineering construction more economical and efficient.

- Corrosion resistance and durability

Geocells are usually made of corrosion-resistant polymer materials, which can resist the erosion of water, chemicals, etc., in the soil, maintain stable performance during long-term use, have a long service life, and reduce the later maintenance costs of the project.

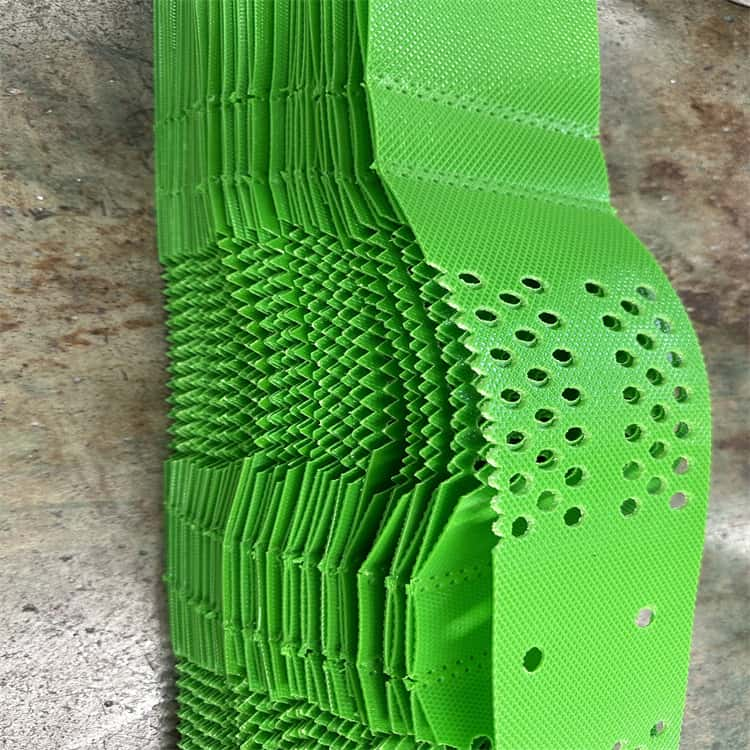

- Convenient and fast construction

Geocells are light in weight and small in volume, making them convenient for transportation and installation. On the construction site, they only need to be unfolded and fixed, and then filled with earth, stone, and other materials. The construction speed is fast, which can effectively shorten the project duration.

- Ecological and environmental protection

Geocells can be combined with vegetation. In slope protection and other projects, after filling the cells with soil, plants can be planted, which not only plays a role in reinforcing the slope but also achieves greening and ecological protection, beautifies the environment, and meets the environmental protection requirements of modern engineering construction.

Overview

Geocell is honeycomb shaped structures,in material of HDPE or PP, welded by high frequency ultrasonic. Being flexible, geocells can be folded in transit and filled with sand, stone, or concrete in roadbed construction. Buried under earth, geocell takes the part of boosting up the carrying capacity of weak ground; sloping surfaces paved with geocells shape a defense framework.

Geocell is our companys main product, with height ranging from 75mm to 250mm and weld spacing from 330mm to 800mm, and its Stripping intensity of welding point reaches 1400N/10cm.

Application

Staling the roadbed of highway

Outspreaded geocells produces high elastic force, reduce more then 50% foundation thickness liken to traditional stone foundation and detract gravity and press in landscape orientation.

Bearing loading press in dykes and walls

Geocells form a certain construction to prevent press in landscape orientation, can be projected staged.

Administering shallow water river way

Be paved in riverside slopes in outspreading form, geocells slow up water walloping, stable riversides bed and support procreation to grow.

Technical Data Sheet

Material | 100% Original HDPE | |

Standard Color | Black Green Tan White | |

Jointing | Ultrasonic Welding | |

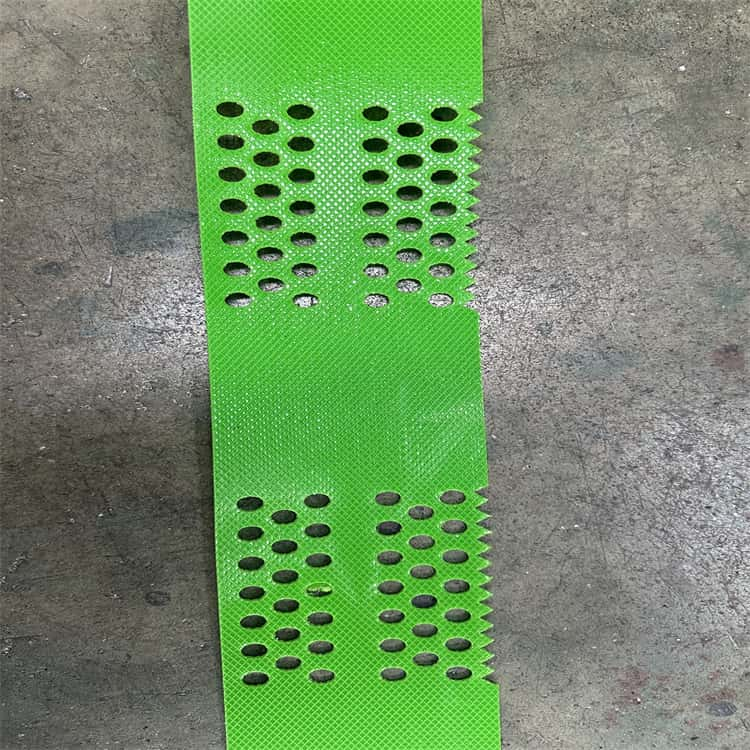

Surface | Smooth, Textured, Perforated, Non-Perforated | |

Density(g/cm3) | >0.94 | ASTM D792 |

Carbon Black Content(%) | 1.5~2.0~2.5 | ASTM D 1603 |

Sheet Thickness(mm) | ≥1.25 ≥1.50 ≥1.75 | ASTM D 5199 |

Seam Peel Strength(KN/m) | ≥14.2 | COE GL-86-19 |

Low Temperature Brittleness(℃) | <-77 | ASTM D 746 |

Environment Stress Crack Resistance(Hours) | >4000 | ASTM D 1693 |

Our Workshop

Customer Visit