PP Nonwoven Geotextile

1. High Strength & Durability

- Excellent tensile, tear, and puncture resistance, capable of withstanding heavy loads for long-term engineering applications.

- Strong chemical stability—resistant to acids, alkalis, corrosion, and insect damage—maintaining stable performance even in harsh environments for extended service life.

2. Superior Permeability & Filtration

- A 3D fibrous mesh structure ensures excellent water permeability, enabling efficient drainage while preventing soil erosion.

- Effectively filters out sand and soil particles, preventing clogging, making it ideal for soil-water separation (e.g., dams, roadbeds).

3. Lightweight & Easy Installation

- Lightweight, reducing transportation and installation costs while significantly improving construction efficiency.

- Highly flexible, conforms to uneven terrain, and can be cut or stitched to meet various engineering needs.

4. Versatile Engineering Applications

- Hydraulic Engineering : Seepage prevention, slope protection, and erosion control.

- Transportation Infrastructure : Subgrade reinforcement, soil separation, and mitigation of reflective cracking.

- Environmental Projects : Landfill liners, filtration layers in wastewater treatment.

5. Cost-Effectiveness

- Low-cost raw materials (polypropylene) and mature production processes ensure high cost efficiency.

- Reduces the need for traditional materials (e.g., gravel), lowering overall project costs.

Summary : Combining mechanical strength, chemical stability, and installation flexibility, it is an ideal material for isolation, reinforcement, drainage, and protection in civil engineering projects.

Overview

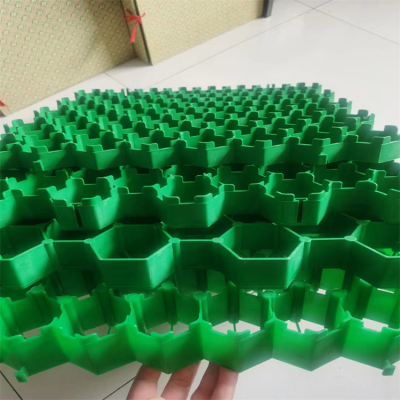

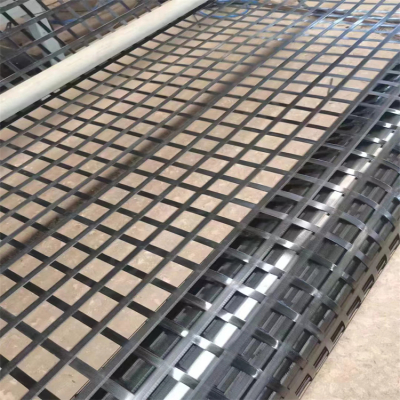

Polypropylene needle-punched nonwoven geotextile is primarily made from polypropylene staple fibers. It is produced through processes such as opening, carding, randomizing, web laying, and needle punching, resulting in a fabric-like finished product.

Features

- Excellent Physical Properties : High tensile strength, tear resistance, and puncture resistance, enabling it to withstand significant external forces without damage. It is also lightweight, facilitating easy transportation and installation.

- Superior Permeability : The fiber-formed mesh structure provides excellent water permeability and filtration. Under soil and water pressure, it allows water to pass through while effectively retaining sand and soil, preventing erosion.

- Outstanding Chemical Stability : Made from polypropylene, it is resistant to acids, alkali, corrosion, insects, and oxidation. It maintains stable performance under various soil and environmental conditions, ensuring a long service life.

Specifications

- Unit Area Mass : Common specifications include 100g/m², 150g/m², 200g/m², 300g/m², 400g/m², etc., with a general tolerance of ±8%.

- Thickness : Increases with unit area mass. For example, 100g/m² has a thickness of ≥1.7mm, while 800g/m² has a thickness of ≥5.0mm.

- Breaking Strength : Measured in KN/m, with requirements for both longitudinal and transverse directions. For instance, 150g/m² has a breaking strength of ≥2.5KN/m, while 800g/m² has a breaking strength of ≥25.0KN/m.

Applications

- Hydraulic Engineering : Used for anti-seepage, filtration, and protection in reservoirs, canals, dams, etc., preventing water leakage and soil erosion. For example, it can effectively retain sand and soil in dam slopes to prevent piping.

- Transportation Engineering : In road and railway construction, it serves as subgrade reinforcement material, a separation layer, or part of the drainage system, reducing rutting deformation and preventing reflective cracks.

- Environmental Engineering : In landfills, sewage treatment plants, and similar projects, it acts as an anti-seepage and filtration layer, preventing pollutant leakage and protecting groundwater and soil environments.

Production Process

Polypropylene staple fibers are first opened by an opener to achieve a loose fiber state. They are then carded by a carding machine into a web of aligned single fibers. A randomizing machine is used to create a three-dimensionally disordered fiber arrangement, forming a uniform fiber web. Finally, a needle-punching machine repeatedly punctures the fiber web with needles, entangling and compressing the fibers to produce a polypropylene needle-punched nonwoven geotextile with specified strength and thickness.

Customer Visit