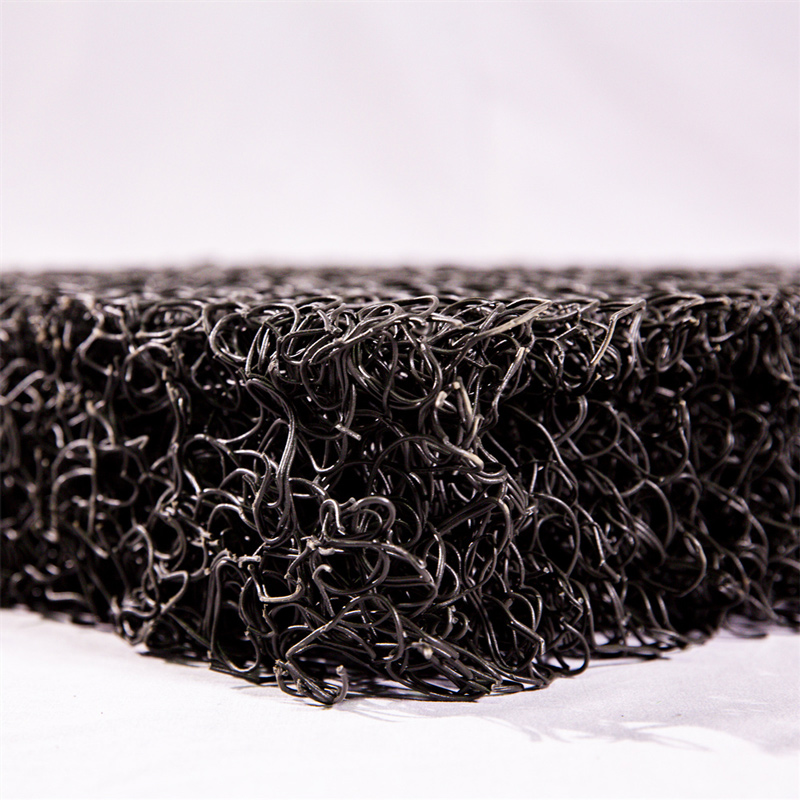

Geomat

The extruded HDPE net drainage core has been designed to withstand extremely high compressive loads with minimal settlement and nearly 100% elastic recovery. Alternative Geocomposites such as those manufactured with cuspated cores collapse without recovery at a specific compressive load (crush) making them more susceptible to site damage during installation. Drainage composites with monofilament cores compress significantly under relatively low pressures which may result in surface settlement and significantly reduced flow rates.

About the Product:

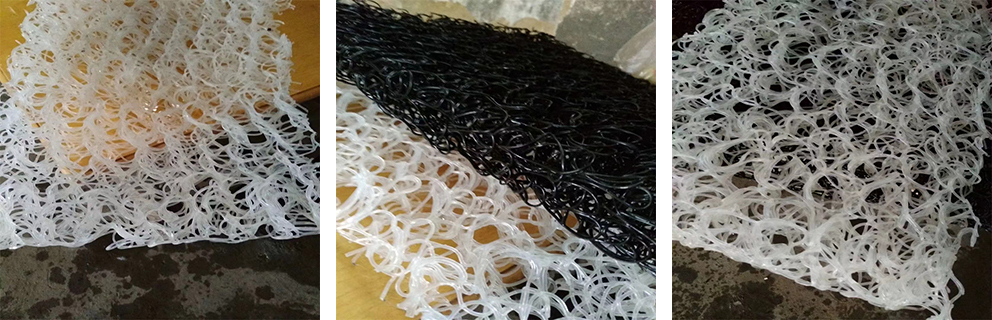

In the hot melting state, the thin plastic wire strip is squeezed out through the nozzle, and then the squeezed plastic wire is fused on the junction through the forming device to form a three-dimensional mesh structure. It can also cover the upper and lower sides with non-woven geotextile.

Technical Parameters:

Specification | SPS-10 | SPS-15 | SPS-20 | SPS-30 | SPS-40 | SPS-50 | SPS-60 | SPS-70 | SPS-80 | SPS-90 | SPS-100 | |

Thickness | 10mm | 15mm | 20mm | 30mm | 40mm | 50mm | 60mm | 70mm | 80mm | 90mm | 100mm | |

Compressive Strength | Compressed10% | 30-150Pa | ||||||||||

Compressed20% | 40-240Pa | |||||||||||

Compressed30% | 50-300Pa | |||||||||||

Porosity | 85-90% | |||||||||||

Horizontal water conductivity | 200KPa,≥50×10-³m²/s | |||||||||||

Characteristics:

High flow under substantial loads

Equivalent to about 12″ (300 mm) of aggregate

Ideal for drainage on slopes

Use:

Landfill liners and caps, road and railway construction, slope stabilization, and drainage systems.

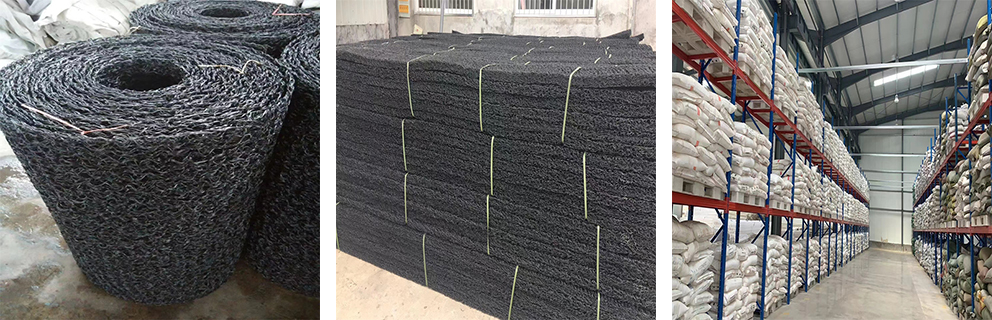

Factory:

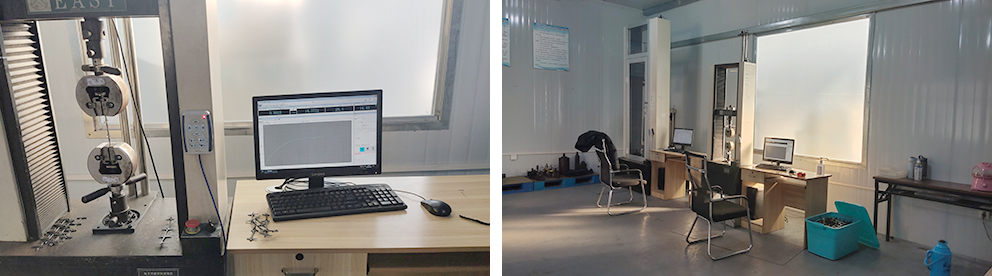

Test Equipment:

Inventory:

Loading:

Client Factory Visit: