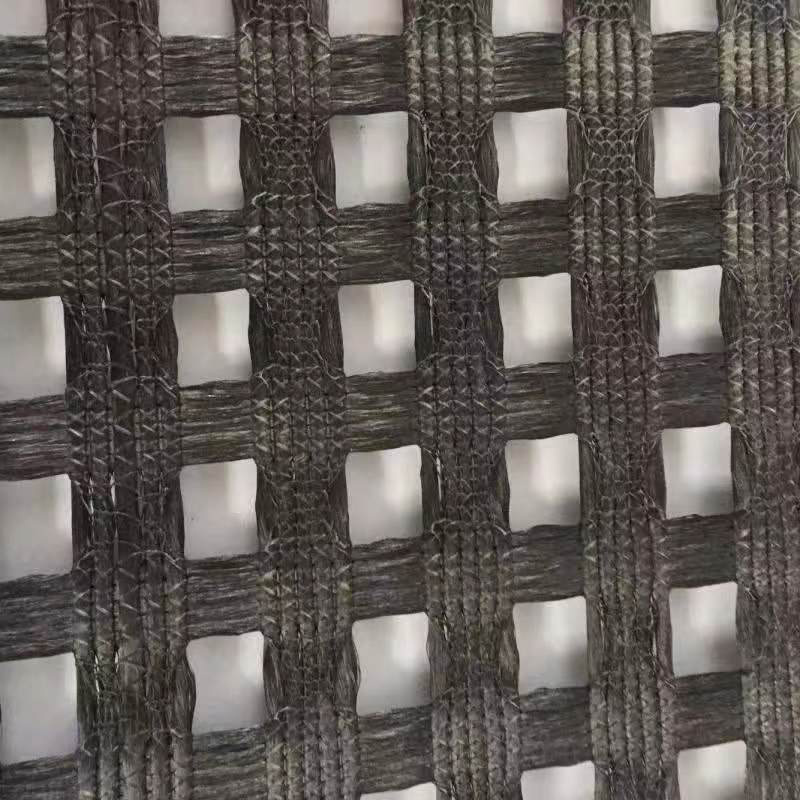

Polyester Geogrid

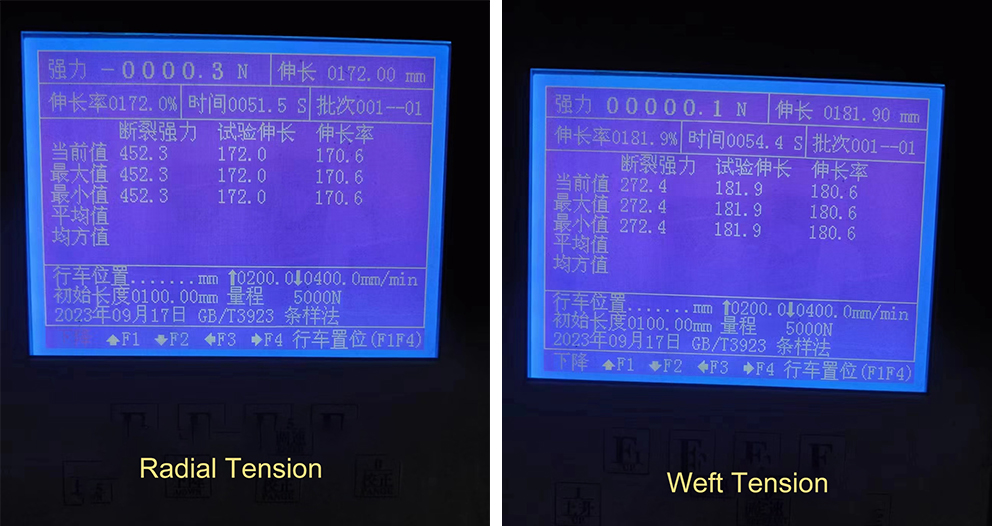

1.Strength;

2.Optimum tensile elongation;

3.High resistance to microorganisms and chemicals in the ground;

4.Resistant to UV rays and mechanical damage;

5.Excellent indicators of interaction between soil and geogrid;

6.Ability to change the raw materials for the custom requirements;

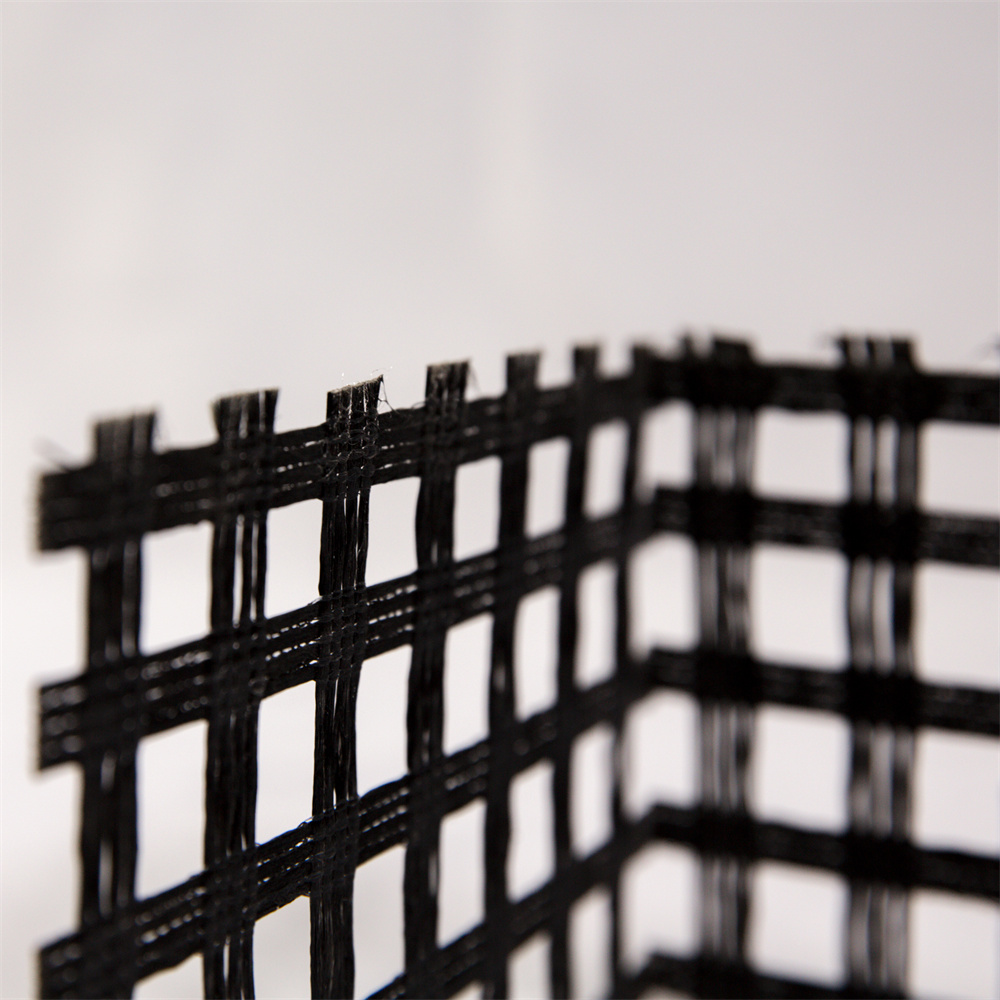

7.Application simplicity and no problems during installation due to flexibility;

8.Very low creep.

Introduction:

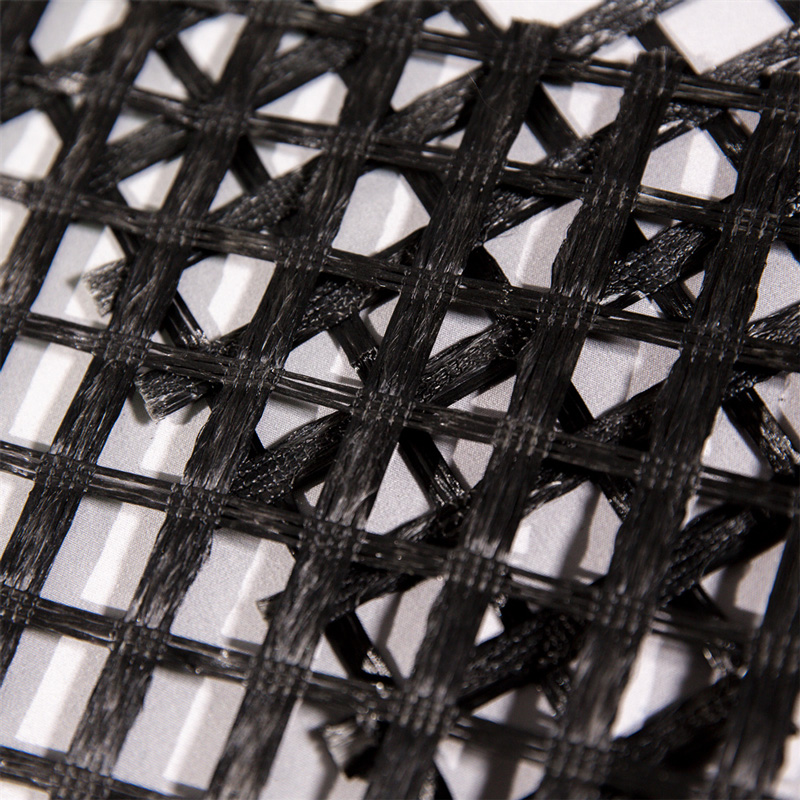

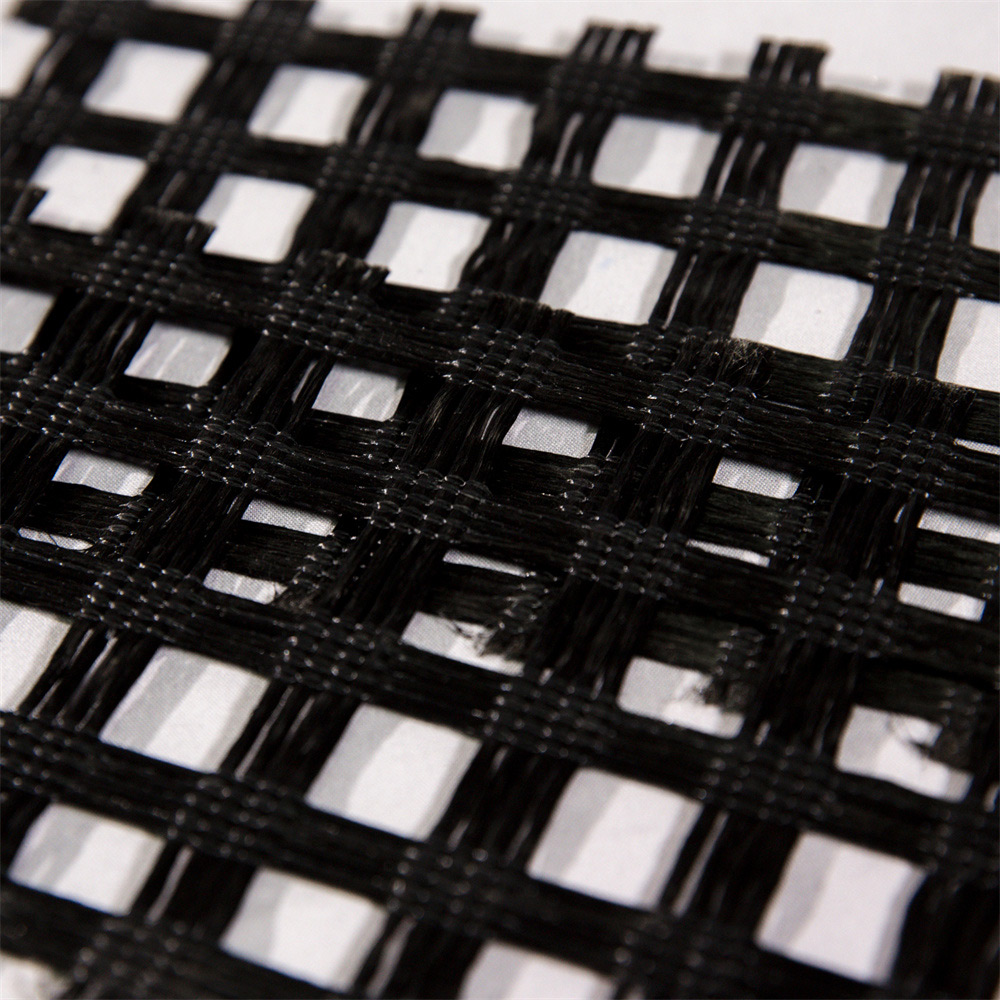

Polyester (PET) type geogrids are made from a woven matrix of high tenacity polyester fibres that are coated with a protective polymer coating. The polyester fibres are oriented in one principle strength direction. Geogrid strengths can be very high, with design values of up to possible 300 kN/m .

Technical Specification:

Performance/Specification | PET-50-5 | PET-60-30 | PET-80-30 | PET-80-50 | PET-100-30 | |

Elongation% | 13% | |||||

Tensile Strength (KN/m) | warp | 50 | 60 | 80 | 80 | 100 |

waft | 50 | 30 | 30 | 50 | 30 | |

Mes size(mm) | 25.4X25.4 | |||||

Width(m) | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | |

Characteristics:

1. Superior Strength and Durability 2. Increased Load-Bearing Capacity 3. Cost-Effective Solution 4. Environmental Benefits 5. Long-Term Performance

Use:

1.Foundations engineering 2.Oil and gas sector 3.Road construction 4.Railroad construction 5.Airfields construction

Plant:

Lab:

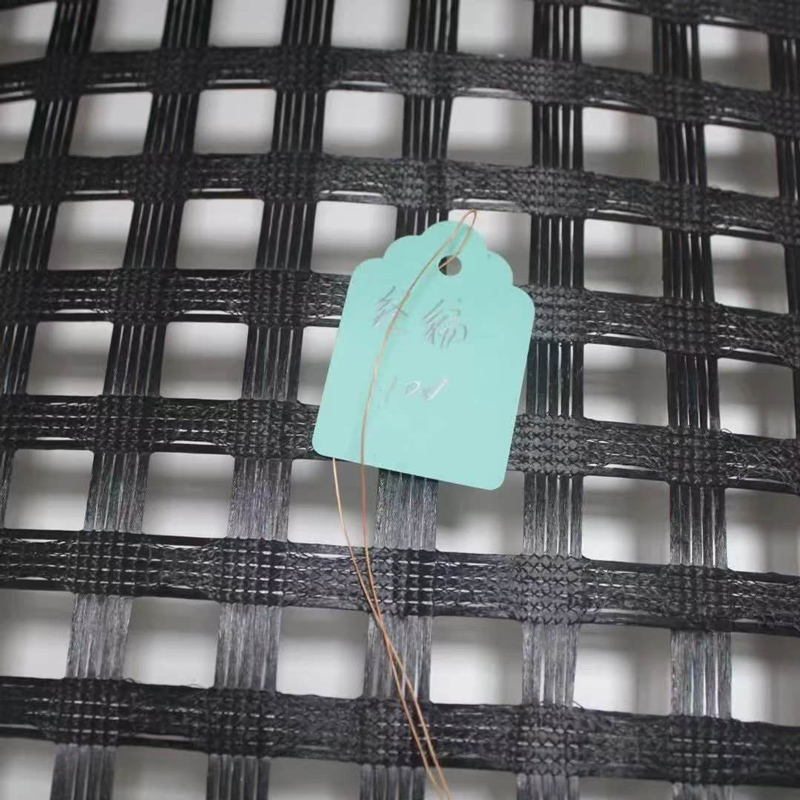

Stock:

Shippment:

Client Factory Inspection: