Fabric Formed Concrete

Fabric formwork is a specialised construction method that uses engineered fabrics to shape and confine in situ concrete as it sets. Typically a lost formwork, the fabric remains in place after the pour, forming part of the final structure, though it rarely performs a structural role once the concrete has set. This technique is particularly valuable where traditional rigid formwork is impractical, such as underwater or in areas with restricted access or uneven profiles.

Easy to roll out and fill for faster installation in tight spaces

Provides rigid scour protection and hill erosion control

Introduction

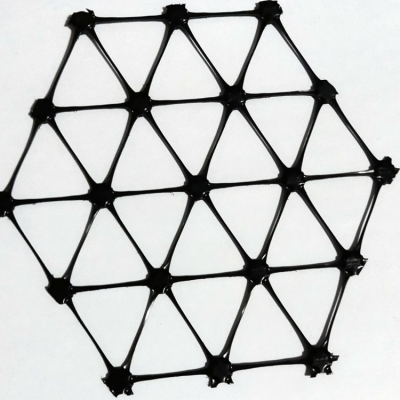

Fabric-formed concrete, also known as grout mattresses,Geosynthetic Concrete Mattress/ geotextile mattress,offers professionals a durable and innovative hard armor solution for erosion control. Not only do these concrete erosion control products stand the test of time, but they also provide superior scour protection. Use fabric-formed concrete systems to stabilize moderately uneven subgrades, provide scour mitigation in underwater zones, or reinforce bridge spill-slopes with low clearances.

Features

Flexible & Adaptable:

Forms around irregular terrain and structural footprints.

High-Quality Concrete Finish:

Porous fabrics allow controlled water bleed for dense, durable concrete.

Lightweight & Easy to Handle:

Ideal for remote, underwater, or congested work areas.

Engineered & Purpose-Made:

Custom-fabricated to suit each project’s specific needs.

Prevents Cement Washout:

Grout-tight yet porous, maintaining cement paste integrity.

Cost-Efficient:

Requires less concrete than traditional methods, reducing material and transport costs.

Applications

Fabric-formed concrete is a double-layered quilted bag woven by a high-strength polyester silk machine as a flexible template, which is pressurized with concrete or cement mortar and hardened to form a high strength plate. It has been widely used in large-scale slope projects with cover for harbor guards and river rehabilitation. The main characteristics are that the earthwork mold bags can be processed according to the engineering topography and landscape, ensuring the formation of fillers such as concrete; The earthen mould bag is suitable for water and underwater construction, does not need to build a fence, and can be organized under various site conditions. The earthen sponge is especially suitable to protect along river embankments and coastal coasts; The earthwork bag slope has good overall quality, does not require large machinery and equipment, doesn't affect navigation in construction, and the construction speed is fast and labor intensity is low. The earthwork bag protective surface does not need to be maintained over the years and the maintenance cost is low. Therefore, earthen moulded slopes have high utility.

Production lines

Customer Visit

Customer Review