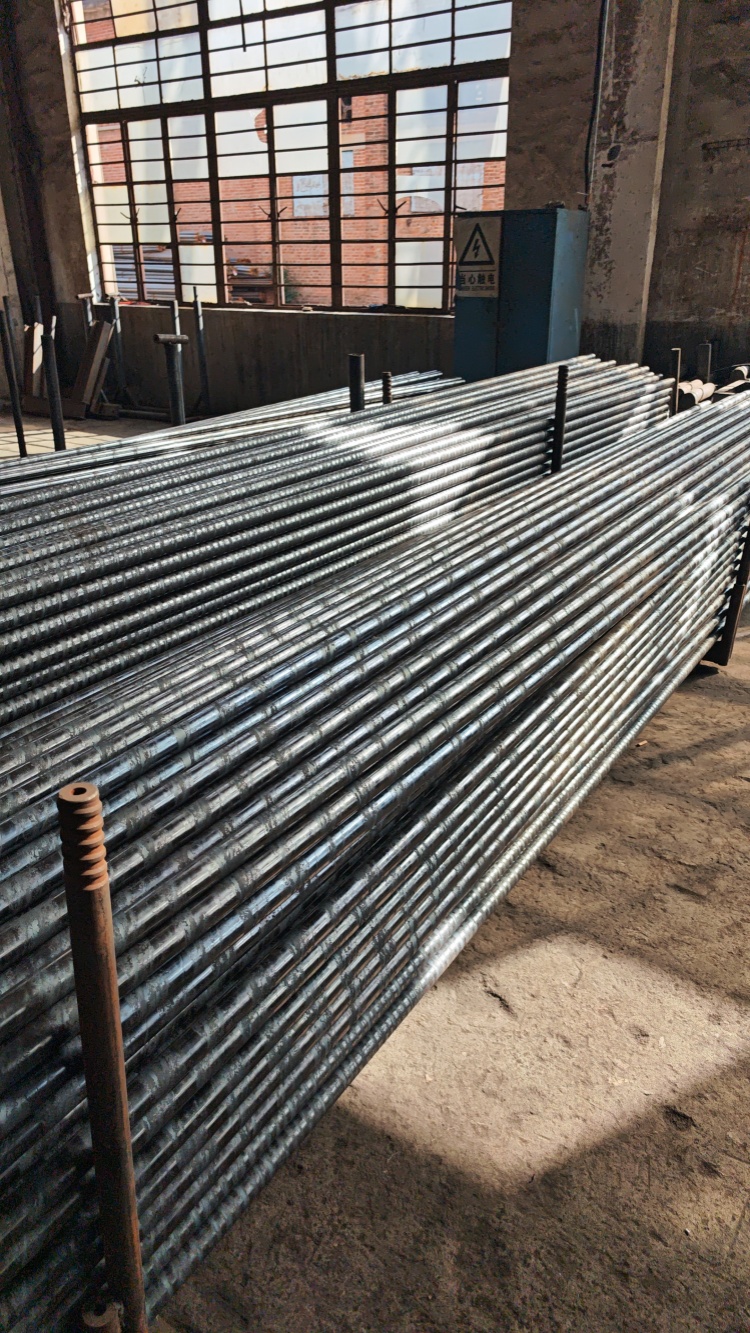

Drill Pipe for Blast Furnace Tapping

1. Superior Material & Quality Assurance: Manufactured from high-grade alloy steel (45# steel, 40Cr, 42CrMo) that meets international industrial standards. The material undergoes strict heat treatment, ensuring excellent fatigue resistance, shear strength, and high-temperature resistance—capable of withstanding long-term stable operation in extreme working conditions.

2. Efficient & Labor-Saving Design: Featuring a gradient drill body structure (diameters gradually increasing from front to rear), it enhances drilling speed and penetration force, enabling quick tunneling through rock, refractory materials, and taphole clay. Loose thread connections between adjacent drill pipes allow for fast assembly/disassembly, reducing maintenance time and labor intensity.

3. Customizable Specifications: Flexible customization of diameter, length, thread type, and product type to meet diverse operational needs of global customers. Standard and non-standard specifications are available, with compatibility with international standard taphole openers.

4. Cost-Effective & Durable: High wear resistance and low failure rate reduce material consumption and replacement frequency, lowering overall operational costs for customers. Strict quality control throughout the production process ensures a long service life.

Product Overview

Drill pipe for blast furnace tapping is a core component of metallurgical production equipment, specially engineered to match blast furnace taphole openers. It is designed to efficiently open blast furnace tapholes for molten iron discharge, with high strength, durability, and adaptability to harsh working environments (high temperature, high pressure, and abrasive materials). Widely used in steel mills, metallurgical plants, and smelting enterprises worldwide, it is a trusted choice for improving production efficiency and reducing operational costs.

Technical Specifications

| Parameter | Details |

| Material | 45# steel, 40Cr, 42CrMo (high-grade alloy steel) |

| Diameter | Standard: 38mm; Customizable for special requirements |

| Length | Customizable, common options: 2800mm, 3400mm, 3600mm |

| Thread Type | Double-end R38, Double-end T38, One-end T38 & One-end R38 (compatible with international standards) |

| Product Type | Hollow drill pipe, Solid drill pipe, Weighted drill pipe |

| Application | Blast furnace taphole opening in steel mills, metallurgical plants, smelting enterprises |

| Certification | Complies with ISO, API relevant standards (customizable according to customer requirements) |

Application Scenarios

Ideal for tapping operations in blast furnaces of various scales, suitable for non-metallic material drilling (rock, refractory materials, taphole clay) in metallurgical production. It is an essential tool for steel mills, smelting plants, and metallurgical engineering projects, widely used in global markets such as Europe, Southeast Asia, Africa, and South America.

Quality Commitment

- 100% raw material inspection and finished product testing to ensure product qualification rate.

- Provide a quality guarantee period (customizable according to customer requirements) and professional after-sales service.

- Technical support: Offer product selection guidance, installation instructions, and maintenance advice to solve customer problems in a timely manner.

FAQ

Q1: Can the specifications be customized?

A1: Yes, we support customization of diameter, length, thread type, and material according to your specific operational needs.

Q2: What certifications do your products have?

A2: Our products comply with ISO and API relevant standards. We can also provide additional certifications according to customer market requirements.

Q3: What is the delivery time?

A3: For standard specifications, the delivery time is 7-15 working days; for customized products, it depends on the order quantity and customization requirements, usually 15-30 working days.

Customer Visit